So after I had calmed down I purchased a new starter from RPD, no idea why or how the solenoid has failed as it was working before I removed it.

Starter fitted (bitch of a job) and coolant topped up, bled as well as I could without running. 20L of VPower added to the tank, flushed a litre through to make sure it was all clean, no issues.

Millers competition running in oil added, plugs removed and I was ready to finally see if I had oil pressure. It felt like a lifetime but it was probably about 15 seconds before I got around 2.5 bar at the filter.

Double checked fluid levels, torqued down plugs,

fuel line and crank sensor on and ready for the start..

Started instantly! Ran for about 10 minutes between 2-2.5K to get the cams bedded in, I will probably do another 10 but I need a helper so I can double check for leaks etc. However I can’t see any issues and oil pressure looks good, it won’t idle (I didn’t really give it a chance) which is probably to be expected with the cams/manifold.

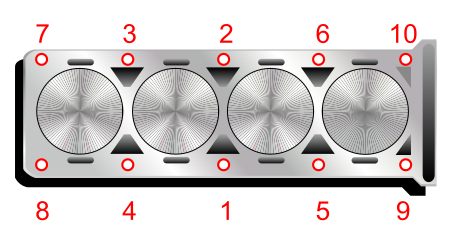

View attachment 155274

View attachment 155275

Time to get booked in for the dyno…

For anyone in the same position this video is very good.