Epic posting mate

Hope this all goes ahead. Although between what you have in the car already, the spare engine (SPARE ENGINE!!!

) and the Recaros... couldn't that all just go towards a proper ground up built motor?

Either way, looking forward to hearing what happens.

Yes, it was a good price for a 21k mile 200 lump so I couldn't say no!

I know what you mean as I didn't necessarily intend when the build was commissioned to go quite as mad, but there is def no point in selling my forged engine as there is nothing wrong with the forged bottom end and I wouldn't actually change anything about it. All it now just needs is a played with head, wilder cams and potentially the induction side of things. - Other than the cams there is no repeat purchasing there...the kick in the teeth is the repeat labour though

The only way to do the bottom end "better" would be short stroke steel crank, 150mm rods, pistons to suit and an 84mm bore on the block. But that setup only makes sense going to 8.5k+, and at that point you're definitely needing solid lifters. Problem with these engines and solids though is due to the cam cover being an integral part of the cam bearings, which means you can't quickly check clearances (valve lash). Also the adjustment on the lifters I've seen are via lash caps over the valve stems and not a bucket and shim with an adjuster that you chuck a feeler gauge in and 20mins later you've sorted the clearances on. So it's a full top end pull apart to adjust them and even just to check is full engine re-time

I had a great idea around designing a custom rocker and dedicated cam bearings etc but christ knows how much it would cost me to get machined - a pipe dream I think!

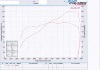

Also that sort of setup is basically R3 Maxi Evo spec and those are rated at 4000KM rebuild schedules! So I would say I've realistically achieved about the optimum you can get on the bottom end with good components balancing performance and service life. The top end IMO needs to stay hydraulic lifters and single valve springs to keep the balance there also. So nothing needs drastically spending as I've got the valves and valve springs already so should just be a port job and new cams. Induction is very much a we'll see what it makes as to if it needs it, the limited slam panel room means tract length is going to be short and on the mytichal 8.5k+ engine that wouldn't be an issue, but on a motor I'm aiming to make peak about 7.5k with a hard limit at 7.8k (maybe 8k but not keen) it very much might rape the midrange.

Amazing mate! Head work will definitely make some improvements, the cast marks on these heads are awful

Good to know, was looking forward to pulling the spare engine apart to look and measure - but now that probably won't happen!

Vaugely tempted to do the headwork with the same cams in fact, arse about that is paying labour twice if I then later do cams. You've timed these engines haven't you? What's it like with genuine tools? Can't be that hard can it like a lot make out?

Yeh buy a twingo 133 shell or something and drop your spare engine in there, that would be giggles!!!

Ha not a chance!! Though would be funny in something like those mk2.5 campus things!!

what a journey thats been..well done..so more to do??

Of course, always more!!!

I mean what else would I do with myself!

When I finally get where I want with the engine I'll turn to suspension. I've a vague idea of where I'll go with it but it'll be thorough from front to rear, bump steer kit etc.

I just have to resist the urge to build a road-going rhd version of this (minus the spoiler as I love um naked!!):

(jesus christ it's pictures like this that ruin me....MUCH WANT!)