Yesterday we went to Snetterton for a track day.

The track day was organised by MSV and despite the weather being predictably sunny, warm and dry, there were only 66 cars booked on. Our plan had been to take the Clio to a track that we knew well to test out the new geo of 4 degrees of negative camber at the front of the car, negative camber of 2.5 at the rear and toe out of between 10 and 15 minutes at the rear. Both of us had thought that the car might be really unstable at the rear and could have been a real handful to push around Snetterton.

In its usual "road" trim the car has 20mm spacers on the back to fill out the arches. When we arrived and put on the track wheels we decided to keep the spacers off of the car on the basis that if the rear geo was unusable we could throw the spacers back on to widen the rear track and give us back some stability.

@EthanMenace

@EthanMenace did the first proper session in the Clio. His feedback was that the car felt looser at the back. Before it had been possible to launch the Clio on turn in and the car would remain stable and predictable throughout the corner, the only downside to this stability was that the car felt like it was fighting you and resisted slightly. The new set up made the car more pointy and easier to turn in, the rear seemed to follow and felt like it could let go if you pushed the car too far.

I did a somewhat slower session and also found that the car was a bit more alive and even though the car had to be respected even I could cope with it.

We finished off the morning sessions taking turns in the car. After every few sessions we had a look at the RaceBox data to see if our lap times were improving. Generally the times were getting better but it was noticeable that the gearbox was causing issues and we were losing time compared to previous Snetterton track days. At the track day the gearbox was "okay" in that it would change gear but most gear changes required patience. You would engage the clutch, move the car out of gear, and then apply a small amount of pressure to put the gear stick in to the right place but have to wait until the box was ready to then accept the gear change. If you were to look at a graph the speed trace shows noticeable drop offs between gear changes compared to other similar runs that owe have done at Snetterton.

Notwithstanding the gearbox issue the day was good fun. There was enough of a mix of cars out on track to find challenges in terms of chasing down or trying to keep ahead. As seems to be the norm these days a few groups turned up in their modern BMW M cars and would go out as a train and do three laps, then have to cool down and come back to the pits. The Clio was good for long sessions on track. The oil temperature gauge crept above 120 on a few stints but all was well with the engine.

The brakes on the car feel very good. Since installing the Megane 3 callipers and bigger front discs we had only been able to test them out at Blyton Park. Snetterton has some longer straights where the Clio will get to about 115 mph before braking.

@EthanMenace kept telling me to brake later and brake harder yesterday. He was right as they take the abuse and do stop the car really effectively

When we finished the day we took a look at the tyre wear to see if the new geo had actually made any difference. The photo below is of the front left tyre. This is the tyre that takes the biggest loads at Snetterton as most of the fast corners are right handers. In the photo the inside edge is on the left and the outside edge of the tyre is on the right. I think that we have worn the inside edge of the tyre less than we would normally, and it looks like we have achieved pretty even wear across the tyre. This might be a placebo effect, particularly as the tyre has also done a session on the rear of the car at Blyton which is an anti-clockwise circuit.

Ethan's best lap time yesterday was a 2m 20s. The Clio has previously done a 2m 18s with Ethan driving it. There could be a lot of reasons why Ethan drove the car faster before but I am pretty sure it is a gearbox related issue.

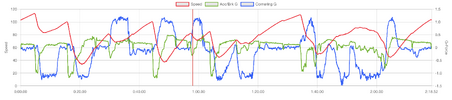

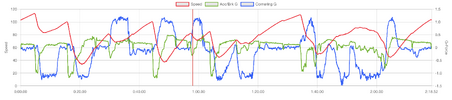

This is a graph from a previous lap of 2m 18s.

This is a graph from yesterday's 2m 20s lap. The G-Force axis on the second graphic a little bit different as it has a maxim value of 2g and not 1.5g.

I am picking at very small details here but the dip in the red speed line suggests to me that a gear change is taking longer than it did on the previous 2m 18s lap.

Helpfully on the way home the gearbox started to noticeably crunch on downshifts in to third gear. This is not at all helpful as we are off to the Nurburgring at the end of the month. I have spoken to Alex at AW Motorworks and he is overrun with work and cannot fit the car in to drop the box and rebuild it before Germany. So, it looks like we/Ethan will have to deal with the gearbox ourselves due to the tight schedule we have got. The slave has already been replaced and has done a few hundred miles. We have a brand new OEM clutch to go in. We also have a separate working gearbox with no LSD in it sat in the shed.

I think that are options are, drop the current gearbox and replace the clutch to rule out that being an issue, and then the options are:

- Put in the gearbox with no LSD and hope that it does actually work

- Put in the second gearbox if the Gripper can be easily moved and dropped in

- Try to rebuild the current gearbox with new synchros and any other parts that look knackered.

Ethan has managed to do everything else on the car so here's hoping he can learn how to rebuild gearboxes in the next few weeks!