have made some small progress since last update.

Weight is down to around 1080kg and working on taking some more out. The alloy seat mount has held up fine to all manner of driving situations and remains completely rigid which is good.

Gave the engine and gearbox an oil change with some expensive millers oil. The oil that came out also showed no sign of anything to worry about which is good. Chucked the old JR pod filter and replaced it with a new ramair proram filter with new silicon elbow etc, waiting on parts to relocate the battery and then will be making some cold air feed etc for that.

I've been looking into alternative alternator solutions to cut weight, but as a decent interim I've fitted a mk2 clio lightweight pulley connected to the standard alternator with a stretch belt. I hacked the alternator bracket in half as well saving another kilo, This setup underdrives the alternator, and allows the tensioner and aircon/idler to be removed saving over 3kg overall.

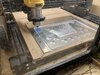

Seeing as i've done the timing belt myself, its always been on my mind to get the car to a dyno to make sure i've done it right and its not down on power, with the weight of the car significantly less than when i started it could mask a loss of power. So I took it through to MB garage services and motorsport near Aberdeen, a lot of sprint cars from the area use them as well as some SLS competitors etc so seemed a good shout,

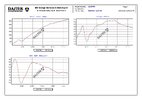

Good news is as suspected the engine is healthy with just the usual flatspot around 3krpm made worse by the removal of the first cat, hopefully having it mapped eventually will get rid of that but its not really a problem. Performance was strong given the spec and the dyno operator got out of the car and basically congratulated me on how well it did, specifically commenting on how normally he'd have backed off the throttle as power started to taper off, but my car was still increasing in power as it hit the limiter. Surprising given its still on the standard cams.

So all in pretty happy and i've got my baseline for future engine mods.