Cadwell Aug 2022.

Only the second track day of the year but I was looking forward to this one, Cadwell has always been a favourite but it's a nemesis of mine! More on this later.

Cadwell is a good 2.5 hours from me so we always try to make a few days holiday of it either side of the Trackday. With fuel prices high, the cost of hotels through the roof and it being the beginning of August we decided to camp over at the circuit for a couple of days.

Loaded up a bunch of us met at Birch services mid day on the Sunday.

Camping was great for me, it was good to get away in the campervan again and get some use out of it, rather than just using it to tow the trailers.

The weather was perfect so once the racing was finished on the Sunday we set up camp and went for a walk around the circuit.

It's always great to see the circuit from a different perspective rather than just inside the car, you can really appreciated the elevation changes and cambers, I made some mental notes of the cambers in some sections of the track to give myself some more confidence the following day.

Unloaded the trailer and did a little lap of the circuit carpark, one downside of the car being off the road totally is the inability to drive it when changes are made and give it a shake down before a track day. You just have to be confident in your spannering skills and your knowledge of the workings of the car

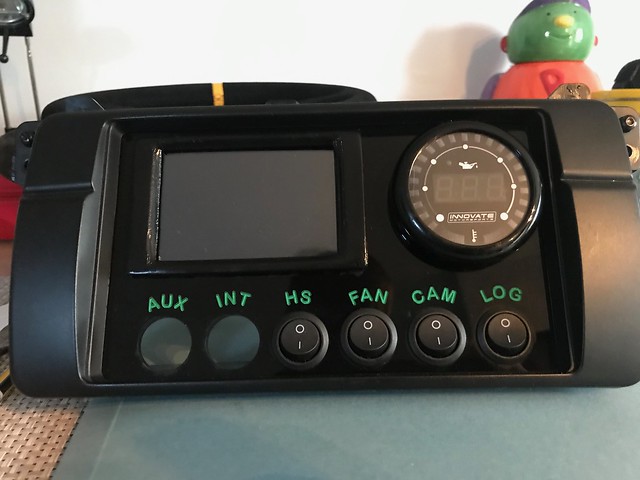

The morning soon rolled around and it was a 7am start, my view for the majority of the day. Pretty simple as far as interiors go, I'm still using the standard E46 clocks being driven by the standalone ECU Via Canbus. Still running the innovate oil temp and pressure gauge for simplicity.

The logger screen offers a few pages of information:

Oil pressure

Fuel Pressure

Oil Temp

Coolant Temp

Front brake pressure

Read brake pressure

Brake bias - I like to see it changing and how I've got the bias valve set.

Two EGT's from the exhaust

Air Fuel Ratio

EGO - Closed loop fuel trim applied by the ECU at achieve perfect AFR's

Max Speed

Max RPM

Min Oil Pressure

Min Fuel Pressure

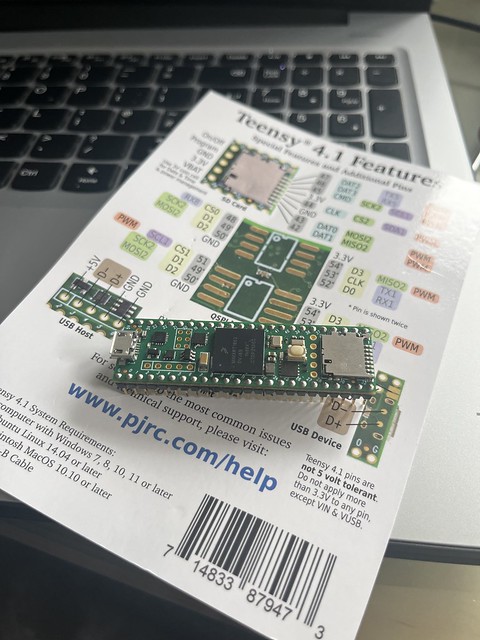

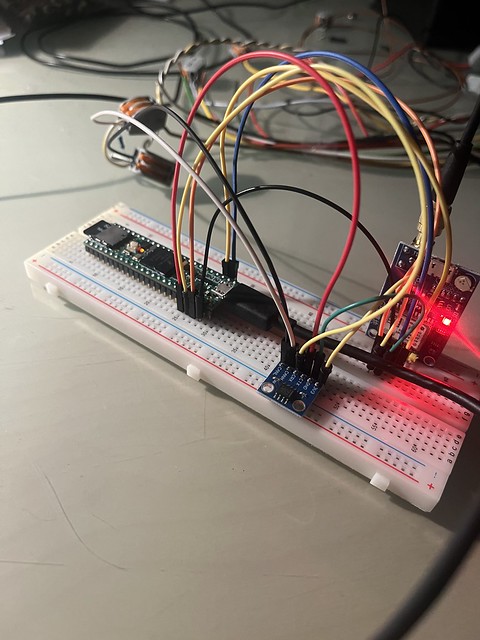

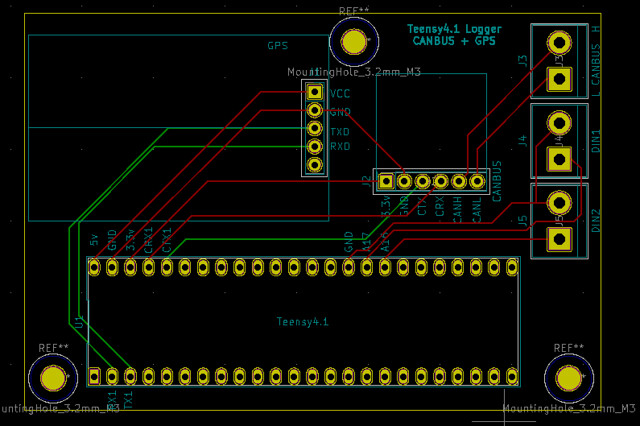

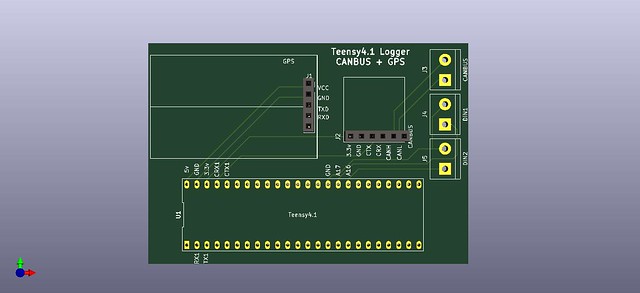

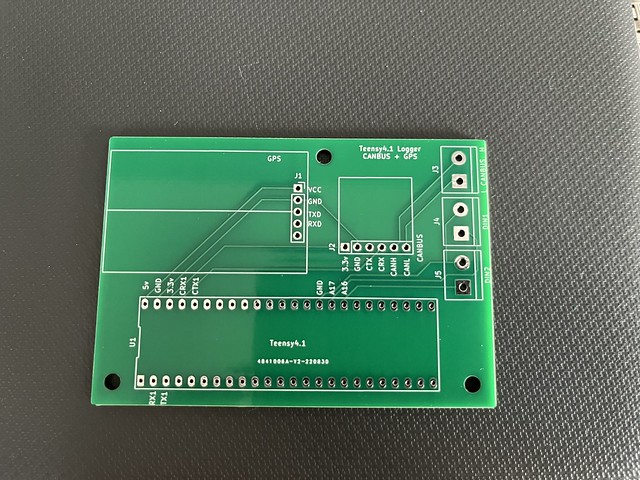

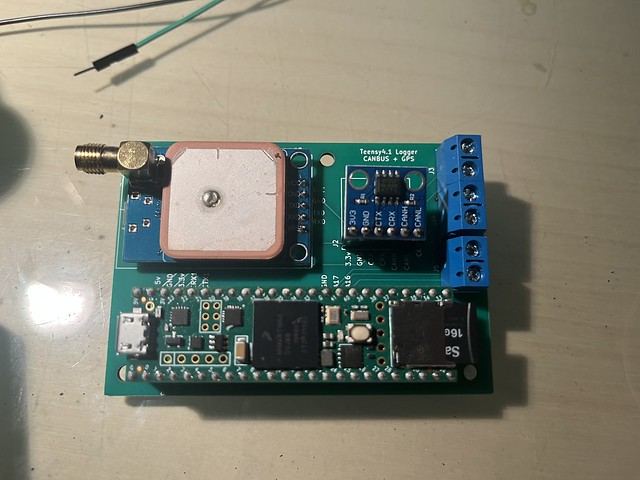

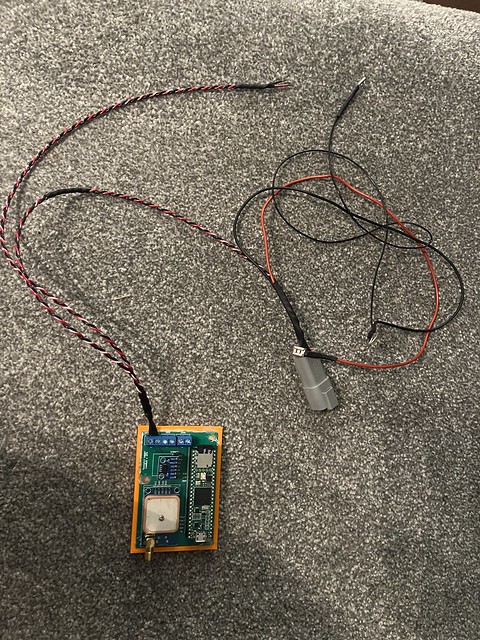

A whole host of other data is available on the Canbus which is all logged to an SD card. Currently only logging at 10hz but it's starting to suffer with processing speeds considering it's all based of an Arduino Uno and an Arduino Mega. So I will be starting to develop a new and improved logger as we go through Autumn, I'll write a bit more about this as I start to work on it, but already have decided on the hardware and set up.

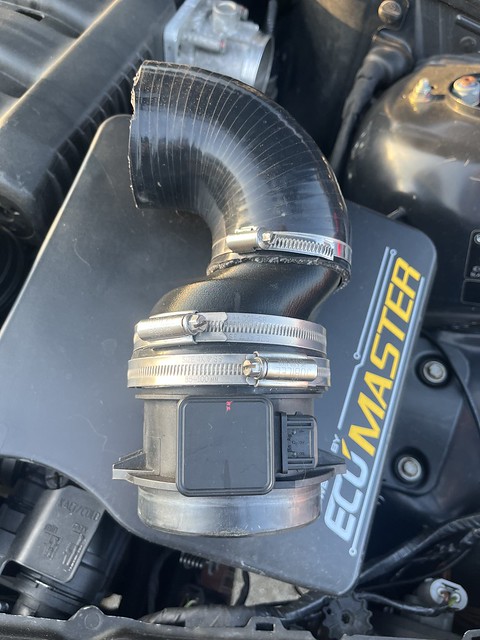

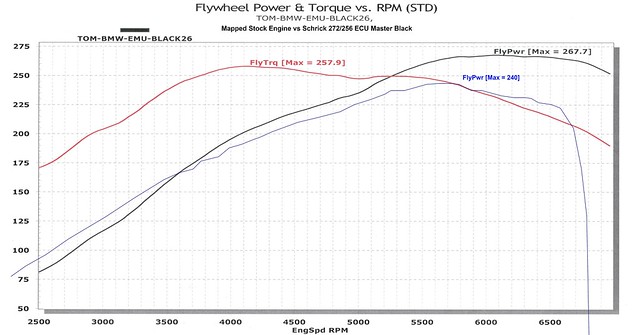

I'd changed a couple of additional things on the run up to the Track day. A ECU Software update a bit of faffing around I have now got the ABS controller and the ECU talking on CANBUS. I now have the ability to view all 4 wheel speed sensors in the ECU which has opened up the ability to start to set up some traction control within the ECU. Currently I only have an enable switch on the dash but Cadwell was a good test to get the basic set up working. I'd took a guess at the wheel slip map and roughed in some traction control ignition cut and timing adjustments when a % of wheel slip was detected so it was good to give this a test in the afternoon and I was pleasantly surprised with the outcome when trying to get the car to slide in the afternoon, I'll be doing some wiring modifications to go with the new logger so I'm planning on adding some rotary switched to adjust the thresholds and effects of the traction control.

The car was flawless all day despite the temperature of the current heat wave. Really surprised at the cars engine and coolant temperatures, I've noticed a big reduction of temperatures since going standalone, must more accurate control over the electronic thermostat on the M54's.

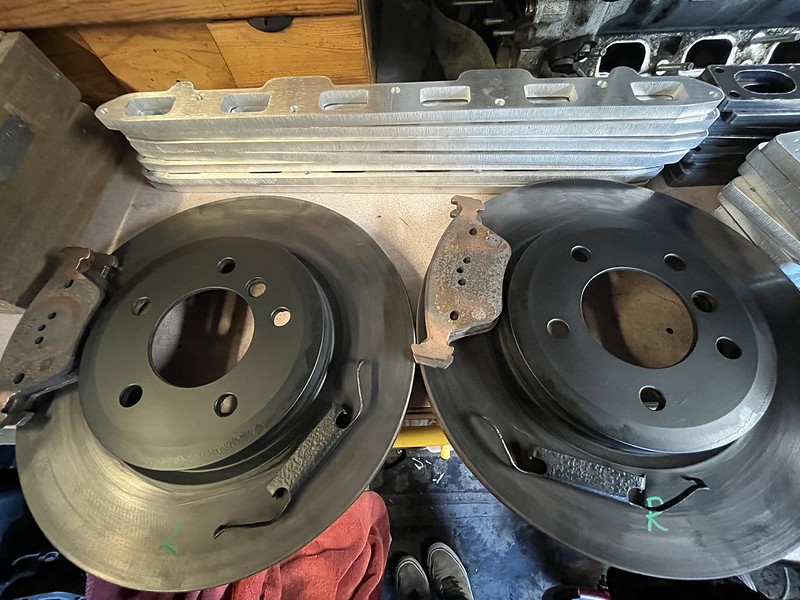

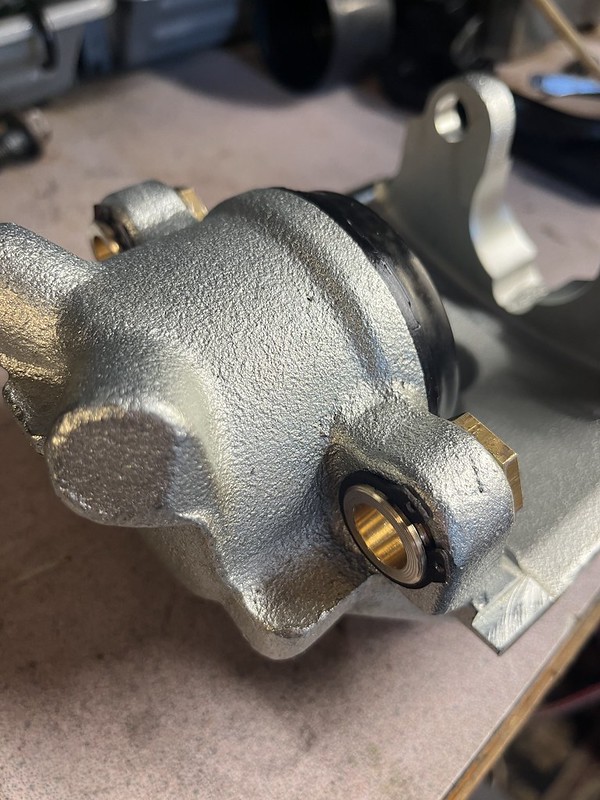

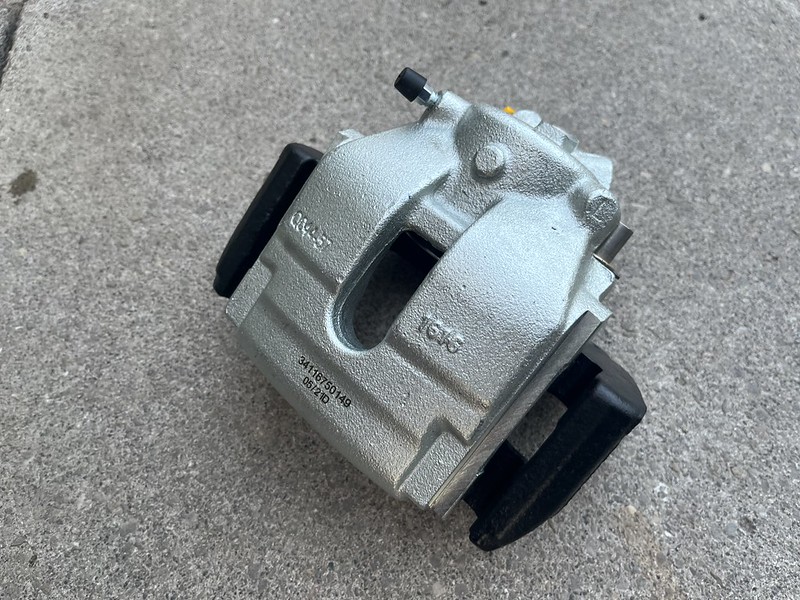

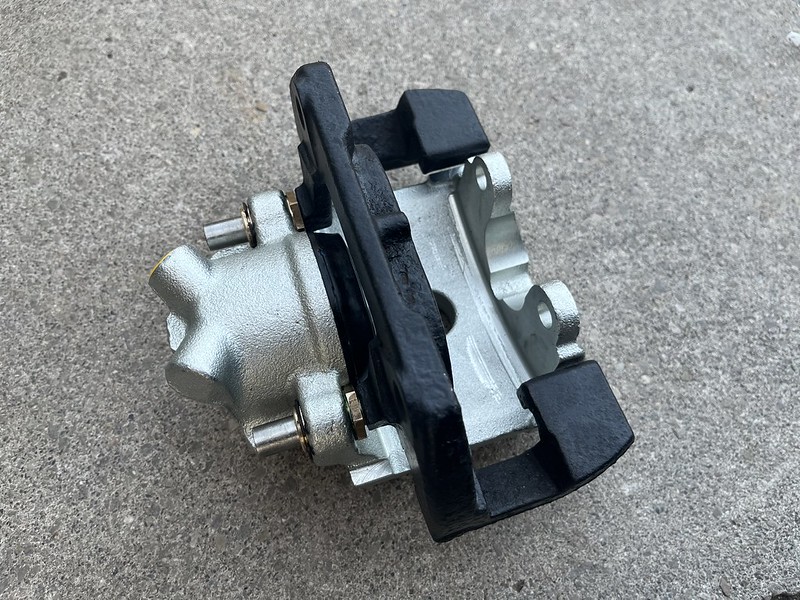

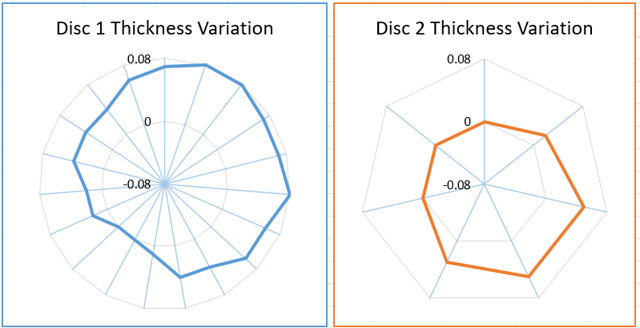

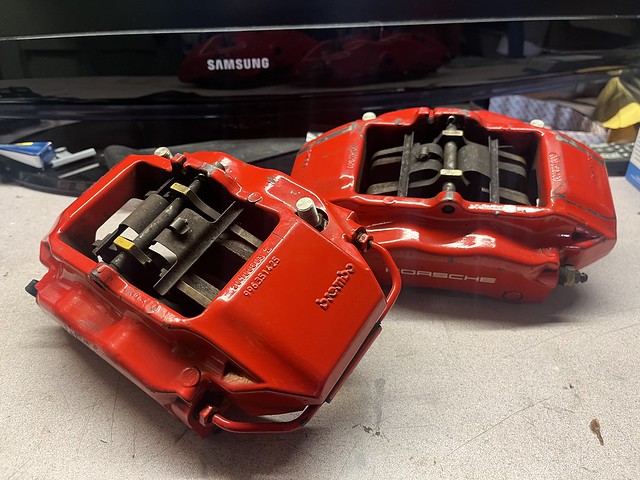

I'm happily able to report that the braking vibration was completely gone, I bedded the DS1.11s in during sighting laps and the first session, now I used to run this prior to 2018 in the Clio so sort of knew the pad, initial impressions are that they bite from a much cooler temperature than the RC6, generally braking power was the same, the RC6 seemed to get better the hotter they hot but the DS1.11s tend to flatline at a certain point, they never faded but I did twice find the limit of stopping of the car down the hill with a passenger in, I'd got used to being in the car all day on my own and the additional 90+ kg weight of the passenger down the hill to Mansfield reminded me that I'm still using standard brakes as I ran slightly deeper into the corner than usual. I did notice that I knocked the braking bias more rearward so was able to use the rear brakes slightly more which would indicate that the fronts did have slightly more bite, probably down to being new pads!

As usual Cadwell Park has always caused me to suffer with terrible sickness, this year was no different, I'd already dropped the drivers window down 2 inches before sighting laps knowing the cabin temps were going to be terrible later on in the day considering it was forecast 30 degree temperatures. Come 11:30 I was really sick, only just making it in off the circuit after just about holding it together for a cool down lap, it's a long way from Hall Bends back to the pits when you're on the verge of being sick! I took an early lunch, grabbed something to eat and a flat can of coke. In the afternoon I went for the spare open face helmet as well as removing my custom ear plugs and was fine all afternoon, whether the ear plugs were causing issues or the full face helmet in the heat, either way I was glad to get on with the rest of the day without issue!

I didn't take many photos throughout the day, it was either spent lapping i the E46 of sat under the awning trying to catch a little bit of shade, but the E46 was flawlessly all day which is a great feeling! I finished the afternoon taking out a couple of passengers who were driving minis on the day, just to show them the difference between the hot hatch and the E46, I do sometimes miss having a hot a hatch, lots of 200bhp cars on trackdays all lapping at similar paces having a great time!

Video of a couple of clear laps

Also managed to get some outside footage of the car, quality of the video isn't great as it's taken on an phone, had a few comments about the induction noise and how the car can be heard from the other side of the circuit at times on full load.

I will give the car a once over in the next week or so, possibly a grumbling wheel bearing to investigate and then start to spend some time deciding on what I want to do with the inside wiring, likely a rewire of the interior loom to add in some extra switches and a new logger.

Be good to here some comments or thoughts from anyone wanting to give any input on the direction I should take the E46 next?