tombate911

Paid Member

As we start to move into spring I've started to look at Trackdays for 2024, I was hoping to get more miles on the car this year, but we'll see how that progresses through the year, noticed a lot of people selling up track cars this year, possibly down to the constant rising of prices and the costs of cars?

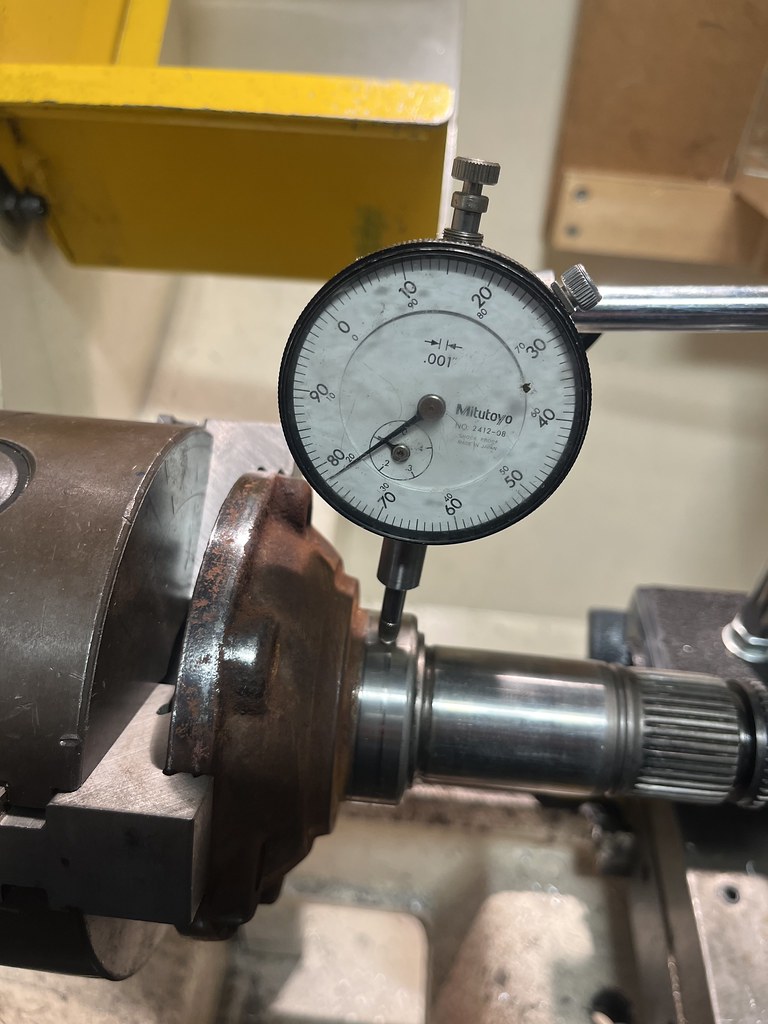

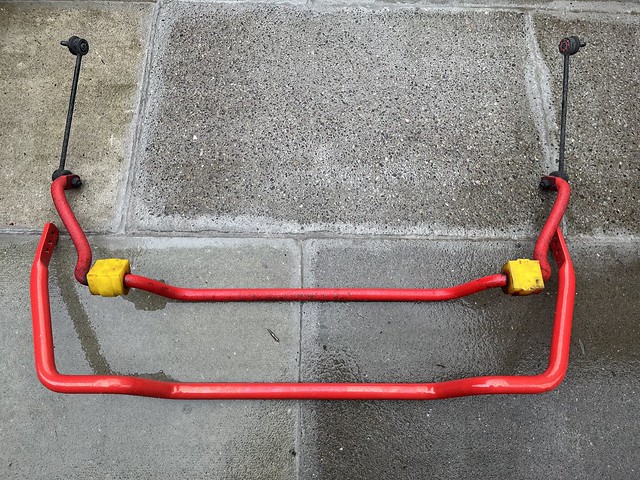

Following on from Oulton I'd made the decision that I wanted to go back to giving ABS a try on the E46. In OEM form I never got on with the ABS and brake system as a whole, the main reason for that is the standard braking system run a 52% / 48% brake bias which resulted in constant intervention from the ABS for the rears. I ditched the system and went with ABS delete and have rated that set up with a Wilwood proportioning valve.

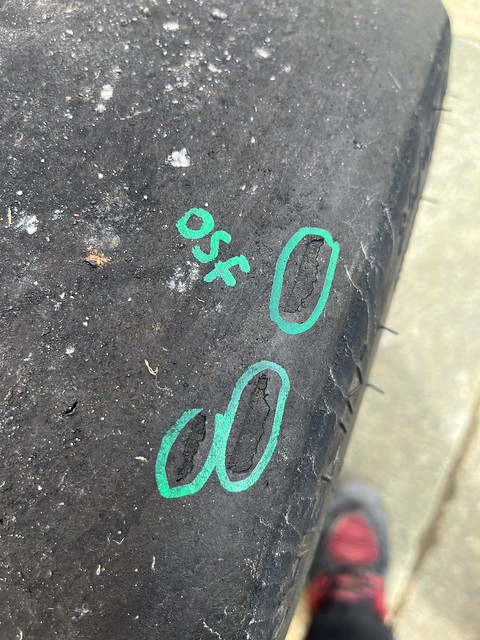

Looking at the data from Track days in 2023 on average the bias is between 60% / 40% - 56% / 44%

Going with ABS one option is to go to a M3 Master cylinder which would bring it down to 53% - 47% but it still isn't in the range I would have become accustomed to and isn't adjustable,

Old Bias location - Prior to removing interior and brake lines.

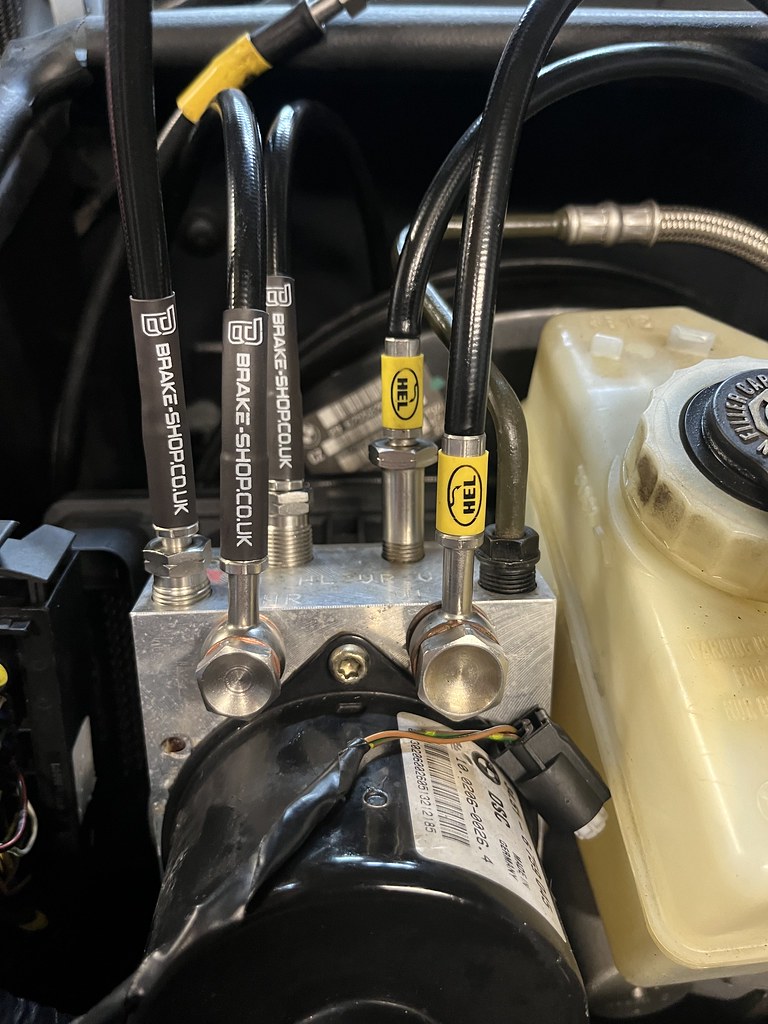

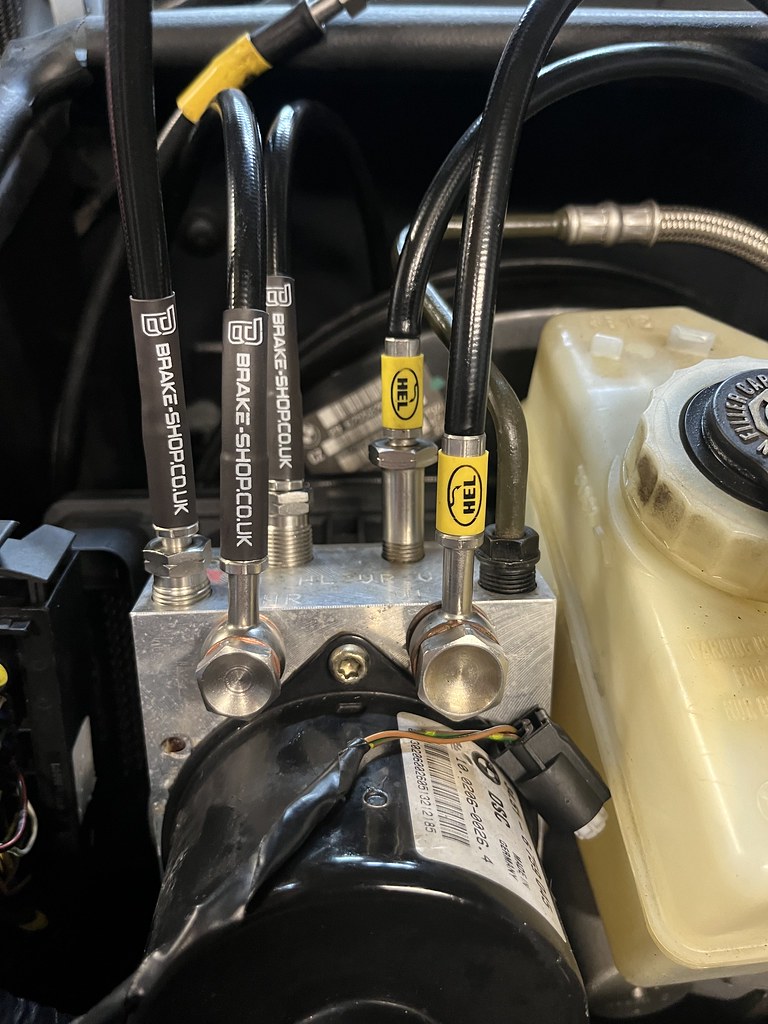

I started using what braided lines I already had on the car for the front lines and refitted the front hard line from the master cylinder to the ABS Pump

Ordered lines for what I didn't have, I reached out to Matt at Brake.Shop.co.uk and ordered some link lines and full lines to go to the rear of the car to join the current braided lines.

Plumbed up the remainder of the ports with braided lines

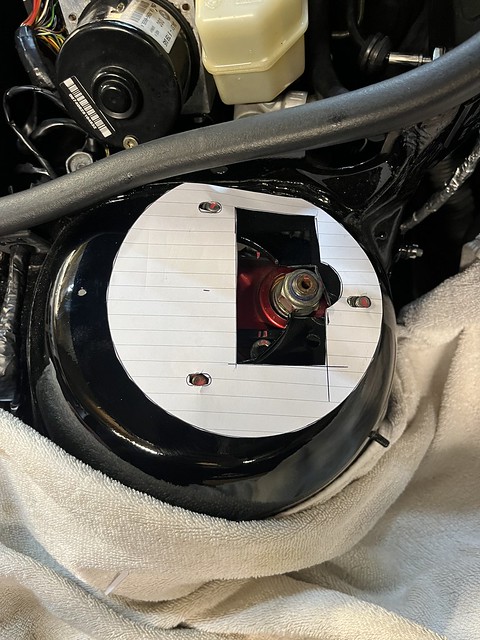

What I have decided to do is take the Rear master cylinder output and ran it to the proportioning valve and ran this back to the ABS Pump.

This gives me the chance to run the same rear bias as before and still utilise the ABS pump.

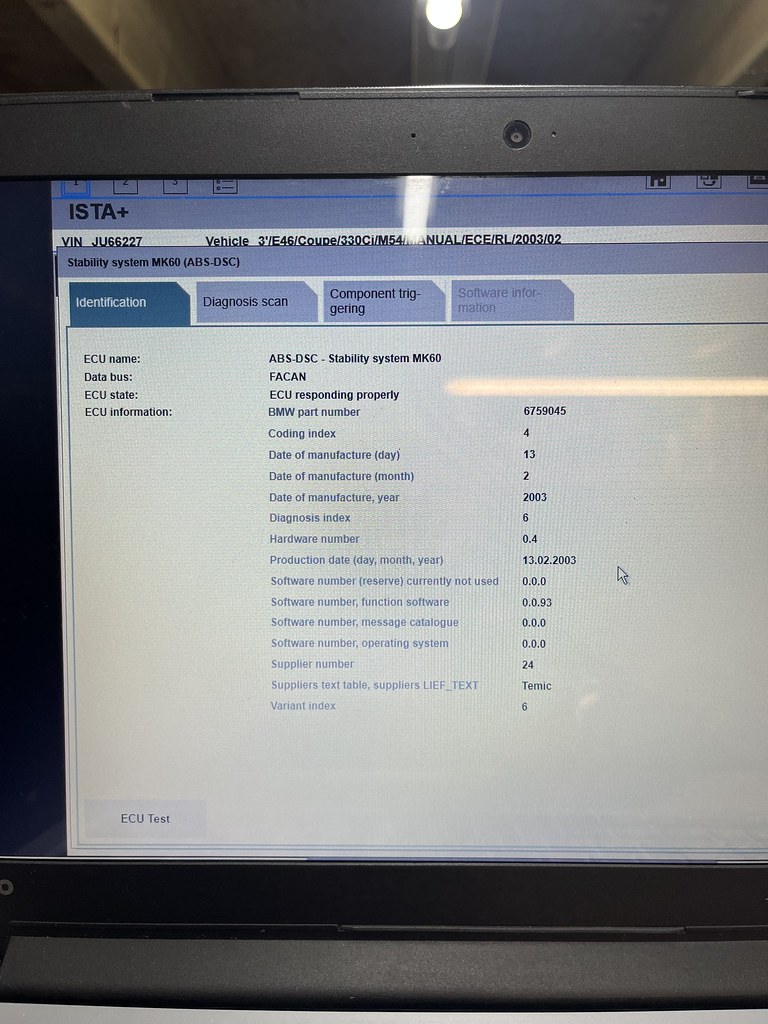

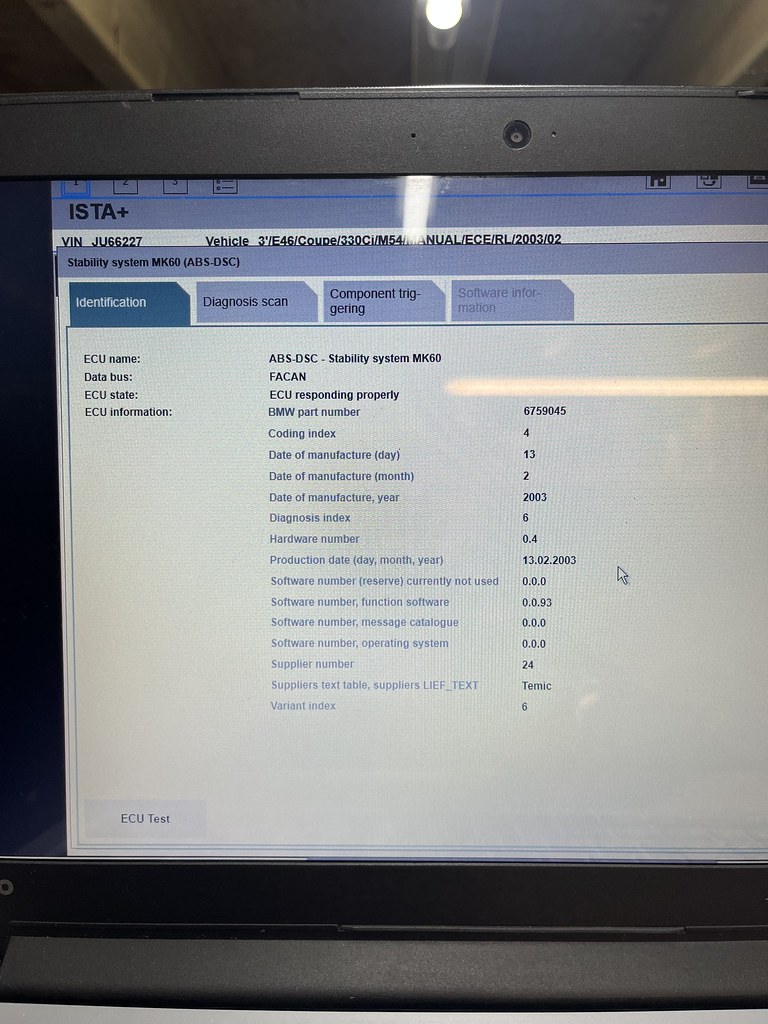

The pump im using is the MK60, this is a really commonly fitted pump to a lot of cars and has a bit online following, There are a range of ABS pump controllers available, some which can be reflashed with different software but that is something to look at down the line, The main advantage is this one is set up for the E46 and just works.

Took a bit of a fiddle but managed to get connected to the MK60 ABS using Ista and INPA. Was good to check the live data as well as going through the function of the ABS switch and fire all the pump to bleed the system correctly, this process took me about 3 days using various different techniques, it wasn't made any easier with the additionally lines and loops I've added to the system.

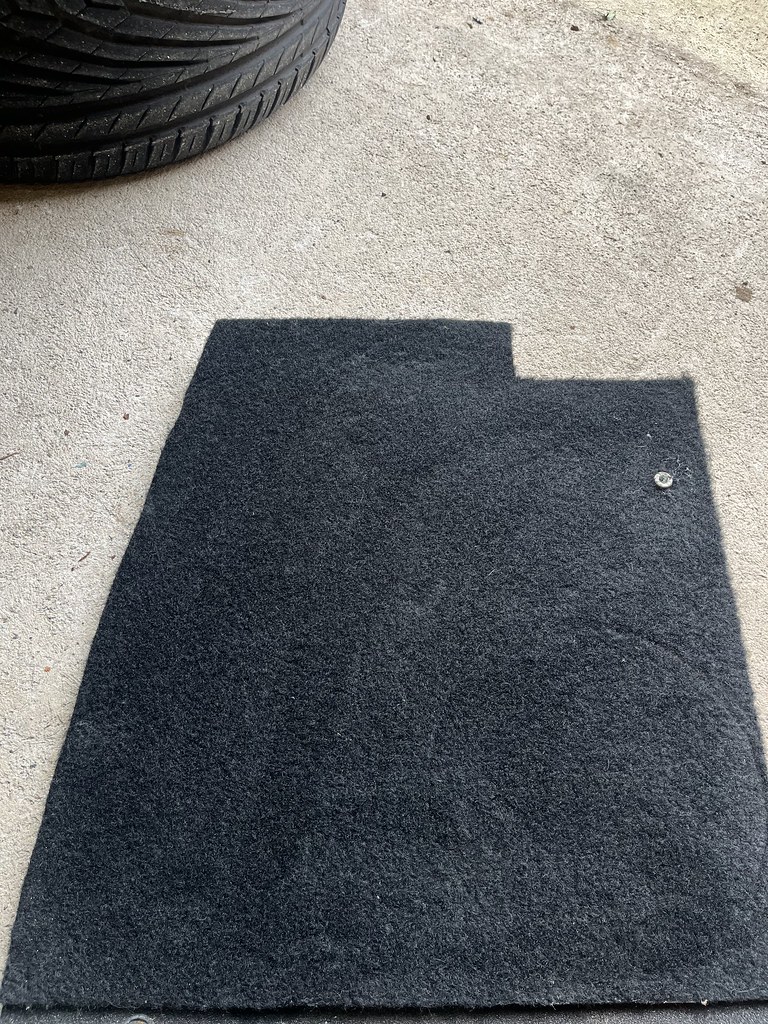

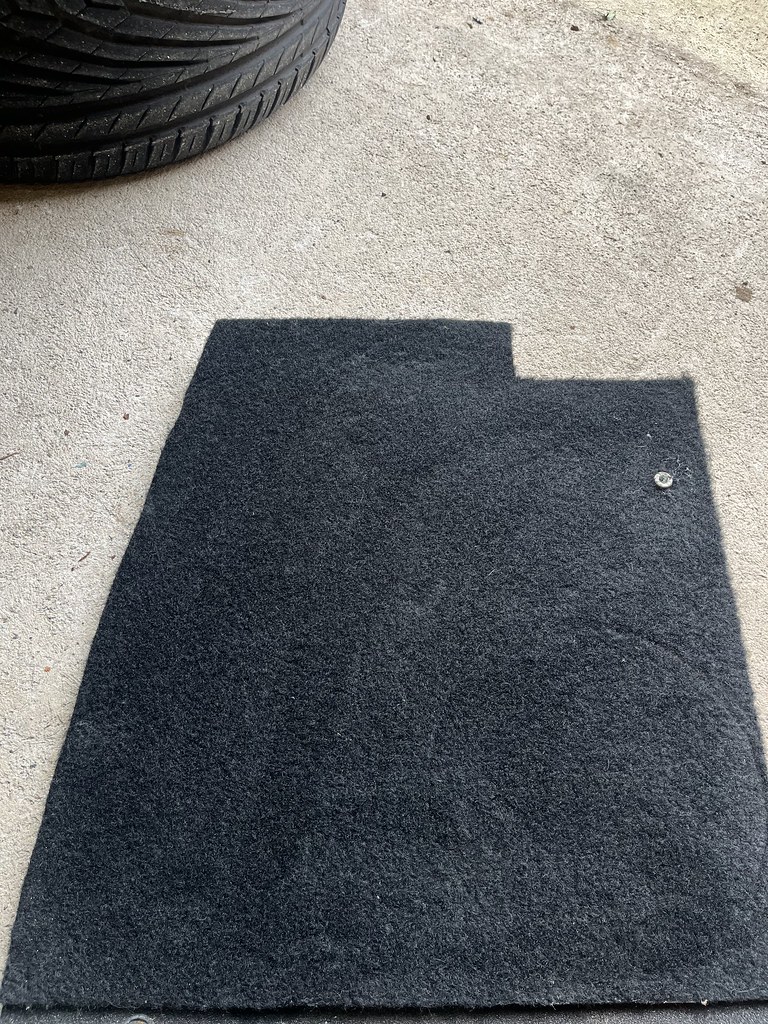

Whilst the seats are out I've removed the driver footplate, I end up replacing the grip tape on this ever two of three trackdays as I tend to dig my left heal into the floor when driving and it pulls the tape off all the time.

At one point over winter I was considering looking for a front carpet, yes I did cut one to bits in 2018 and throw it in the skip, oops, how things change, but the work needed to get one and then refit it I decided i would just carpet the foot plate.

This is one change I am really happy with, it's tidier and just feels nicer.

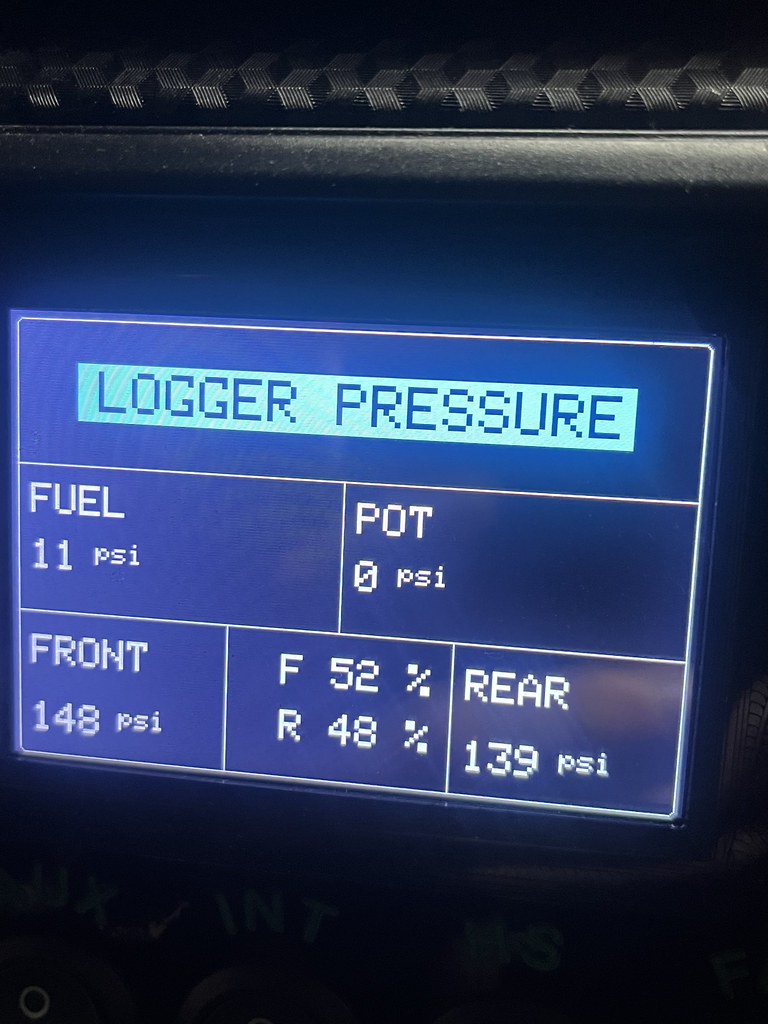

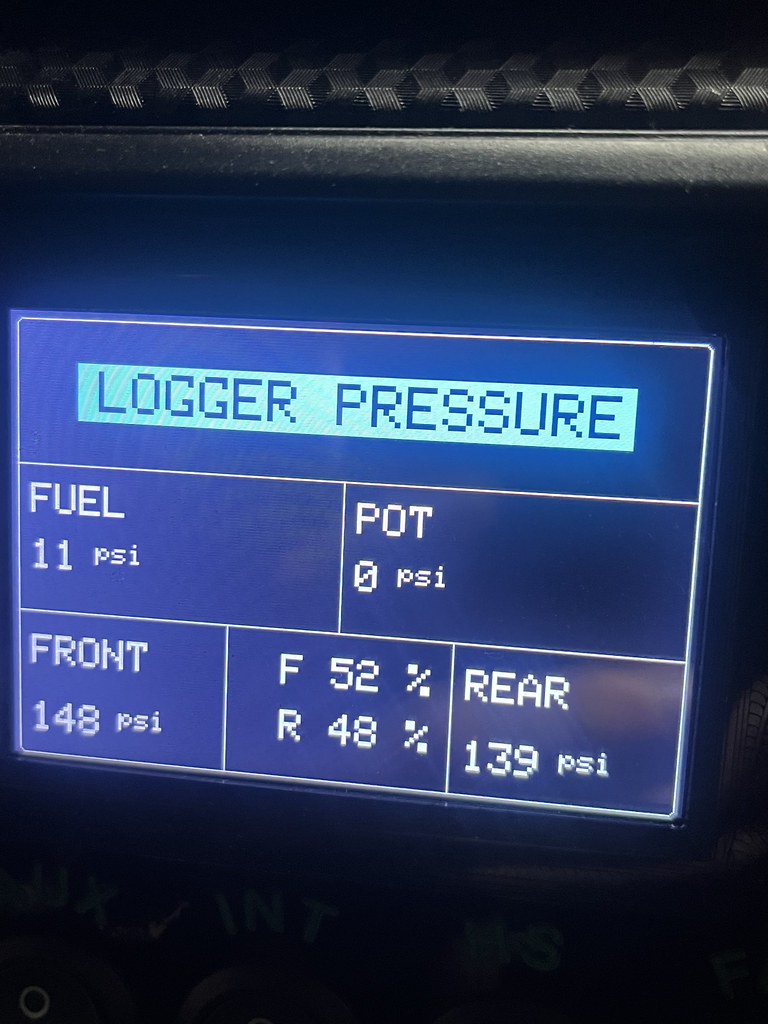

Last few changes have been to the logger and the screen.

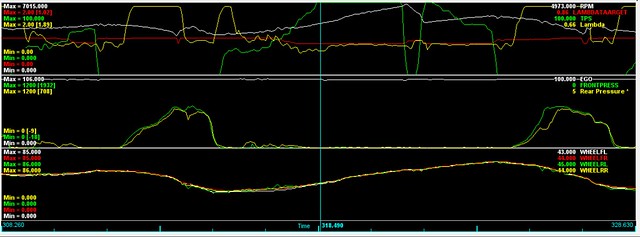

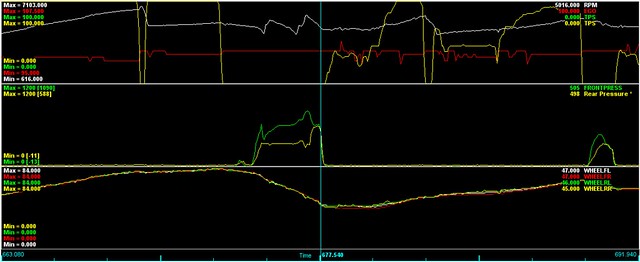

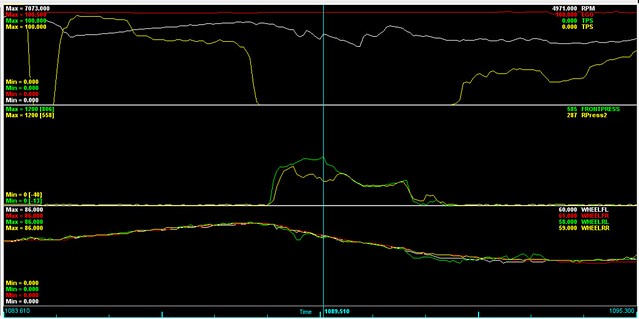

Added a lot more Canbus channels to the logger from the ECU as well as adding some more data to the screens relating to the brakes. Bias viewable on the fly.

I have also been working on a screen which monitors and logs wheel lockups and slip rates when braking in straight line, hope it will be interesting to use as data for dialing in braking and actually seeing what the wheels are doing.

At some point I will update the graphics on this display to something which is a little easier on the eye and 'fancy' but for the time being function!

I am keeping my eye out for a replacement drivers seat too. Looking for a Sparco Circuit to match my current seats but waiting for the right seat at the right price at the moment.

I'm sure there will be more before Cadwell in April. I am looking at some form of graphics and colour being added to the car before then but that is a bit of random idea at the the moment... Watch this space.

Following on from Oulton I'd made the decision that I wanted to go back to giving ABS a try on the E46. In OEM form I never got on with the ABS and brake system as a whole, the main reason for that is the standard braking system run a 52% / 48% brake bias which resulted in constant intervention from the ABS for the rears. I ditched the system and went with ABS delete and have rated that set up with a Wilwood proportioning valve.

Looking at the data from Track days in 2023 on average the bias is between 60% / 40% - 56% / 44%

Going with ABS one option is to go to a M3 Master cylinder which would bring it down to 53% - 47% but it still isn't in the range I would have become accustomed to and isn't adjustable,

Old Bias location - Prior to removing interior and brake lines.

I started using what braided lines I already had on the car for the front lines and refitted the front hard line from the master cylinder to the ABS Pump

Ordered lines for what I didn't have, I reached out to Matt at Brake.Shop.co.uk and ordered some link lines and full lines to go to the rear of the car to join the current braided lines.

Plumbed up the remainder of the ports with braided lines

What I have decided to do is take the Rear master cylinder output and ran it to the proportioning valve and ran this back to the ABS Pump.

This gives me the chance to run the same rear bias as before and still utilise the ABS pump.

The pump im using is the MK60, this is a really commonly fitted pump to a lot of cars and has a bit online following, There are a range of ABS pump controllers available, some which can be reflashed with different software but that is something to look at down the line, The main advantage is this one is set up for the E46 and just works.

Took a bit of a fiddle but managed to get connected to the MK60 ABS using Ista and INPA. Was good to check the live data as well as going through the function of the ABS switch and fire all the pump to bleed the system correctly, this process took me about 3 days using various different techniques, it wasn't made any easier with the additionally lines and loops I've added to the system.

Whilst the seats are out I've removed the driver footplate, I end up replacing the grip tape on this ever two of three trackdays as I tend to dig my left heal into the floor when driving and it pulls the tape off all the time.

At one point over winter I was considering looking for a front carpet, yes I did cut one to bits in 2018 and throw it in the skip, oops, how things change, but the work needed to get one and then refit it I decided i would just carpet the foot plate.

This is one change I am really happy with, it's tidier and just feels nicer.

Last few changes have been to the logger and the screen.

Added a lot more Canbus channels to the logger from the ECU as well as adding some more data to the screens relating to the brakes. Bias viewable on the fly.

I have also been working on a screen which monitors and logs wheel lockups and slip rates when braking in straight line, hope it will be interesting to use as data for dialing in braking and actually seeing what the wheels are doing.

At some point I will update the graphics on this display to something which is a little easier on the eye and 'fancy' but for the time being function!

I am keeping my eye out for a replacement drivers seat too. Looking for a Sparco Circuit to match my current seats but waiting for the right seat at the right price at the moment.

I'm sure there will be more before Cadwell in April. I am looking at some form of graphics and colour being added to the car before then but that is a bit of random idea at the the moment... Watch this space.