tombate911

Paid Member

Is there any reason why you went with the Arduino as opposed to something like a Pi Zero? Looking at doing something similar myself with an LCD/OLED/e-ink display and would only need one analogue input but any advice you could provide would be appreciated.

Always good to read the write-ups on your 330 Tom. This car is part of the reason I bought my 330!

I could probably read back and check but what tyres did you run before the AR-1? I have in my head you ran 595RSRs but I could be wrong. I only ask as my phone doesn't like this forum...

Perhaps it’s worth doing a leak down as opposed to compression?

When's your Snetterton date Tom? I might try to get on the same date, I'd love to see this beast in action!

Brilliant read as usual Tom, love your write-ups.

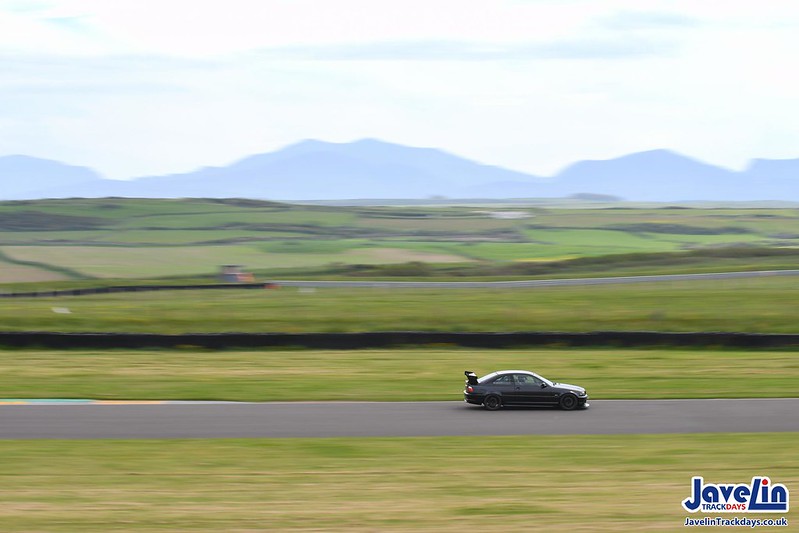

Anglesey is still someplace I haven't driven, been a passenger a few times now, on my wish list.

Is that a PSDesigns shifter you have? the 360mm one? How do you find it?

Can't wait to see you on track so I can nosey round it.

Anglesey is such a good circuit. I did it a lot in the Clio... Including one of the Renault Sport days there. Here's some early photos of the 200 before the cage was fitted. Some of my favourite Clio photos

Yeah it's the RTD Shifter from PSDesigns. They are all very similar in design to the CAE shifter. It is the long race shifter at 360mm combined with the DSSR linkage between the shifter and the box and it's amazing, feels so precise and makes driving the car much more enjoyable.

Be good to let you have a look around it at some point as I know you've always taken a great interest in it. a few of us have booked Snetterton with Track Obsession in August if you're around.

Yep I remember seeing your old 200 there, it's just one of those tracks I've never got to go on (that and Spa), I will definitely get out there.

Awesome thanks for that, been looking at a few, like you said they're all so similar.

Yep I'm at Snet then, I'm back in a track E36 328i (in Boston Green), so it would be great to have a chat and catch up.

Keep the posts up, always a great read Tom

| Thread starter | Similar threads | Forum | Replies | Date |

|---|---|---|---|---|

|

|

197 & 200 albi blue hy500 07.10.23 | Spotted | 0 | |

|

|

Albi Blue RS 200 Intro | New Members | 26 | |

|

|

For Sale: 2007 Clio 197 Albi Blue | Clios For Sale | 1 | |

| P | Renault Clio 200 2009 76k Albi Blue £3400 MOTd | Clios For Sale | 2 | |

| P | Hello - Albi Blue 200 | New Members | 9 |