VeiRoNv2

Paid Member

Haven't seen a thread with all of the torque settings before,if there is one please just close this one,if not hope this is of help.

| Engine | |

| Note: Always renew stretch bolts and self-locking nuts | |

| Cylinder head | |

| Renew the bolts | |

| Renew the gasket | |

| Stage 1 | 30 (Nm) |

| Stage 2 | 155 - 205 (°) |

| Valve cover | |

| Stage 1 (Bolts 13, 20, 22, 23) | 8 (Nm) |

| Stage 2 (Bolts 1 - 12, 14 - 19, 21, 24) | 12 (Nm) |

| Stage 3 (Loosen bolts 13, 20, 22, 23) | |

| Stage 4 (Bolts 13, 20, 22, 23) | 12 (Nm) |

| Big-end bearing cap | |

| Renew the bolts | |

| Stage 1 | 25 (Nm) |

| Stage 2 | 104 - 116 (°) |

| Main bearing cap | |

| Renew the bolts | |

| Stage 1 | 20 (Nm) |

| Stage 2 |

| Sump | |

| Stage 1 (Bolts 1 - 6) | 15 (Nm) |

| Stage 2 (Bolts 7 - 10) | 18 (Nm) |

| Stage 3 (Bolts 11 - 22) | 18 (Nm) |

| Stage 4 (Bolts 1 and 2) | 18 (Nm) |

| Sump (Gearbox side) | 44 (Nm) |

| Engine oil drain plug (Renew the seal) | 20 (Nm) |

| Spark plugs | 28 (Nm) |

| Oil filter | 10-14 (Nm) |

| Knock sensor | 20 (Nm) |

| Oxygen sensor | 45 (Nm) |

| Starter motor | 38 (Nm) |

| Alternator | 25 (Nm) |

| Camshaft bearing caps | 10 (Nm) |

| Camshaft gearwheel | 30 (Nm) |

| Crankshaft pulley | |

| Stage 1 | 40 (Nm) |

| Stage 2 | 100 - 120 (°) |

| Ancillary drive belt tensioner | 50 (Nm) |

| Timing belt tensioner pulley | 32 (Nm) |

| Timing belt idler pulley | 50 (Nm) |

| Timing cover | |

| Stage 1 (Lower section) | 9 (Nm) |

| Stage 2 (Upper section) | 38 (Nm) |

| Flywheel | |

| Stage 1 | 30 (Nm) |

| Stage 2 |

| Exhaust manifold (Stud bolt(s)) | 9 (Nm) |

| Exhaust manifold (Nuts) | 30 (Nm) |

| Inlet manifold | 15 (Nm) |

| Ignition coil | 15 (Nm) |

| Coolant pump | 17 (Nm) |

| Oil pump | 24 (Nm) |

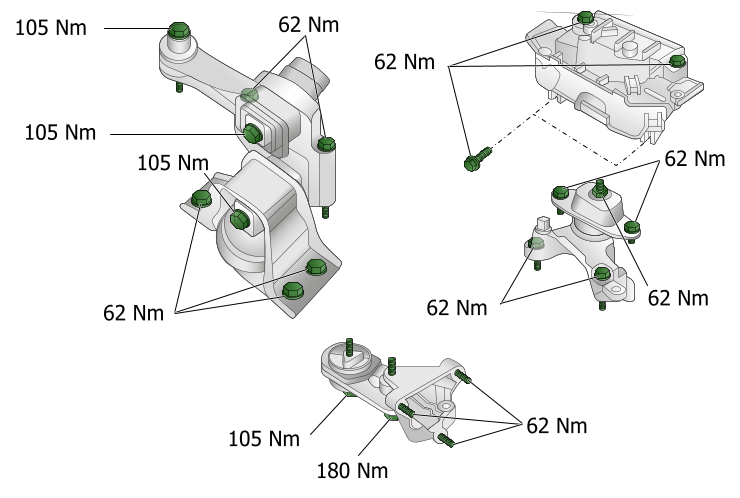

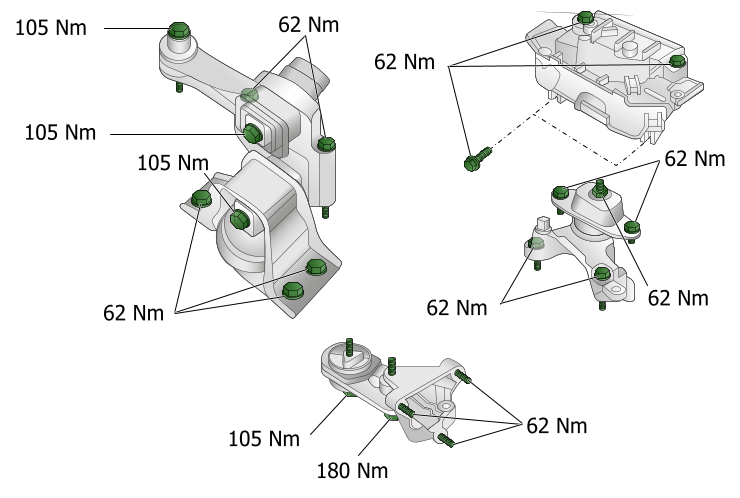

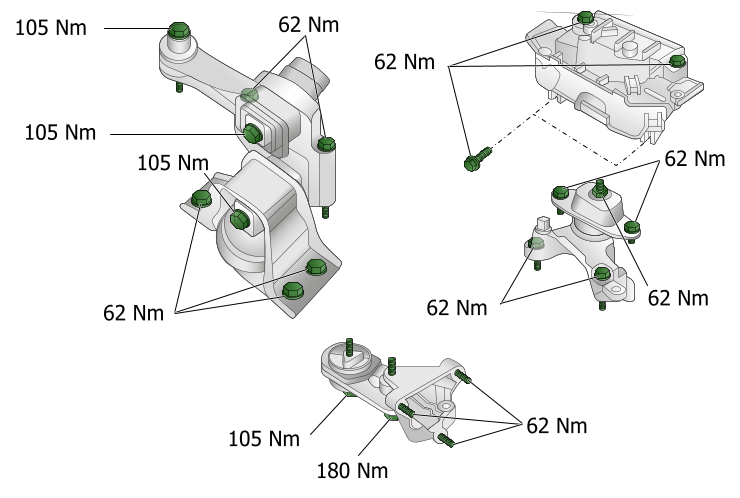

| Engine/gearbox mounts | |

| Manual transmission, TL4, 6-speed | |

| Manual transmission drain plug | 24 (Nm) |

| Clutch pressure plate | 20 (Nm) |

| Suspension | |

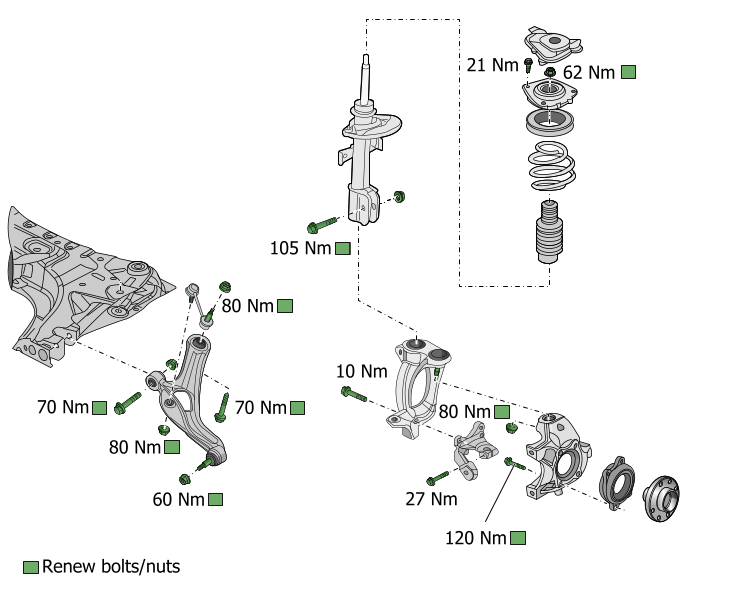

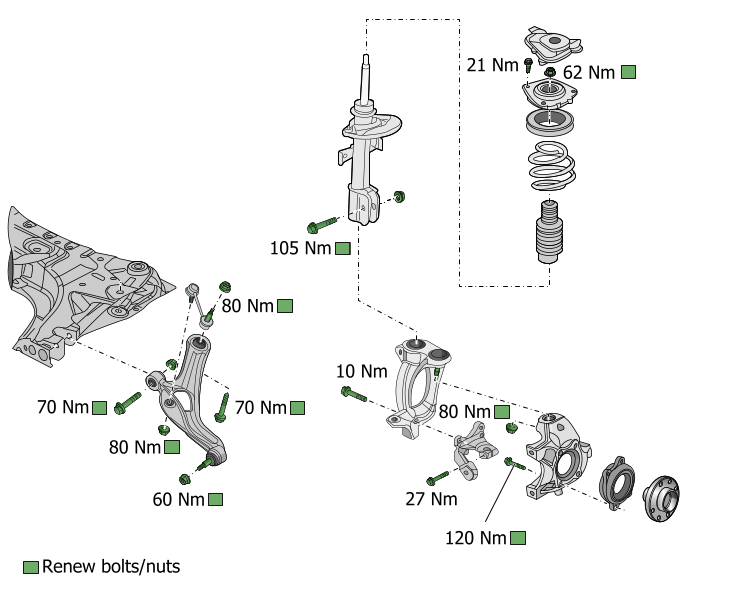

| Front drive shaft to wheel bearing housing | 280 (Nm) |

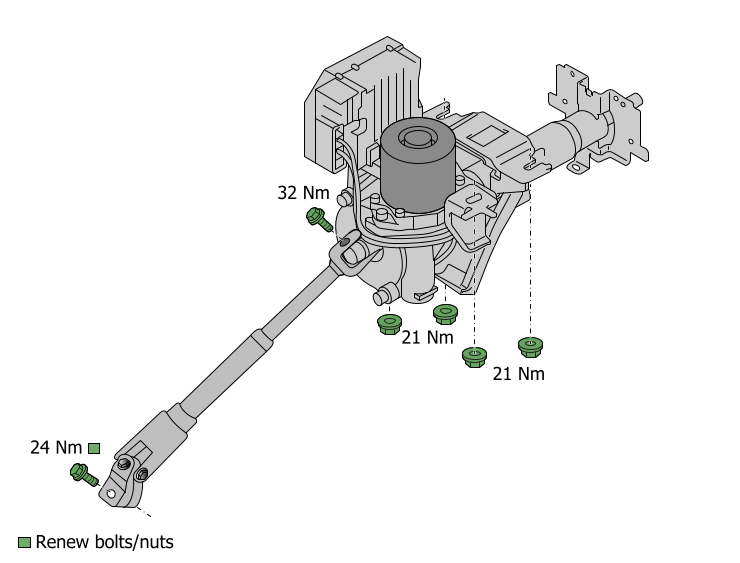

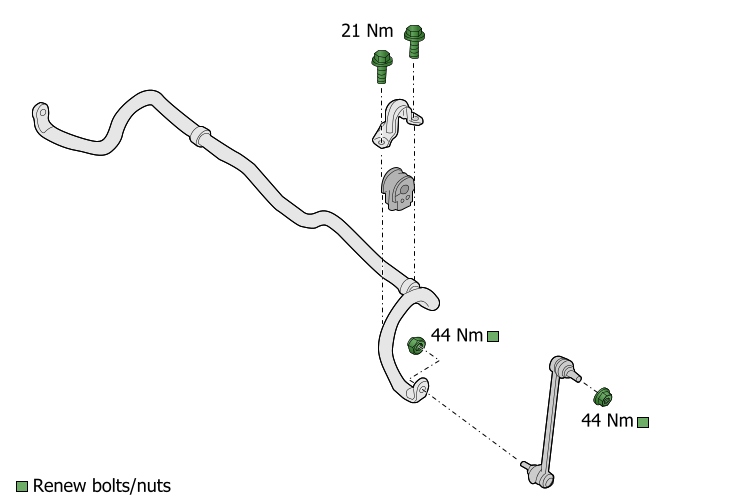

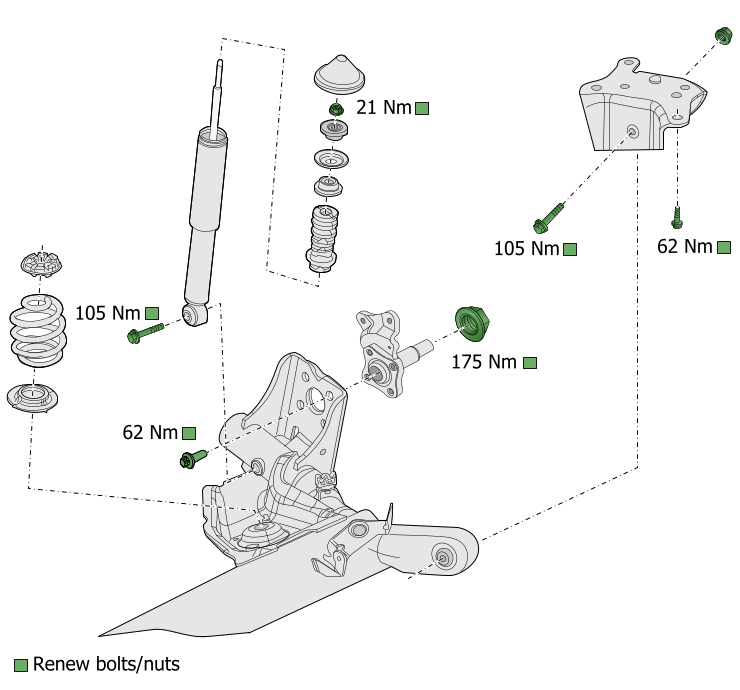

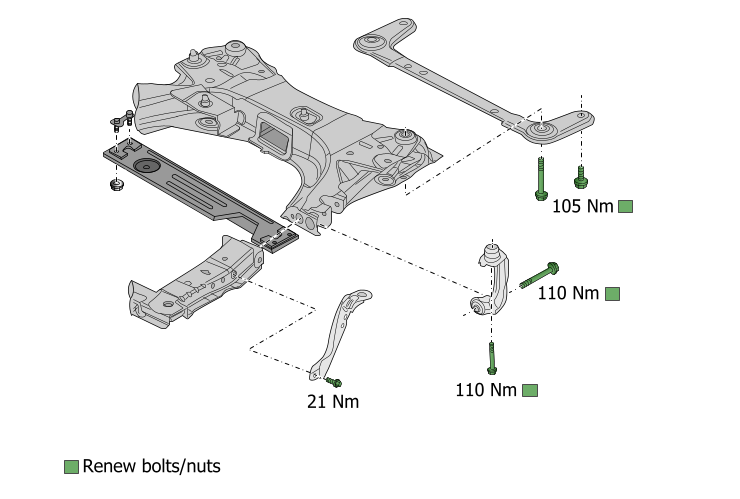

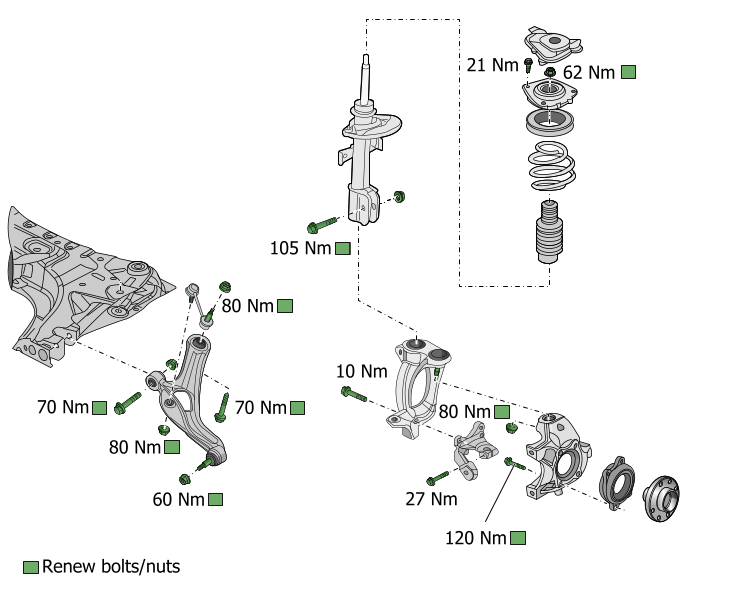

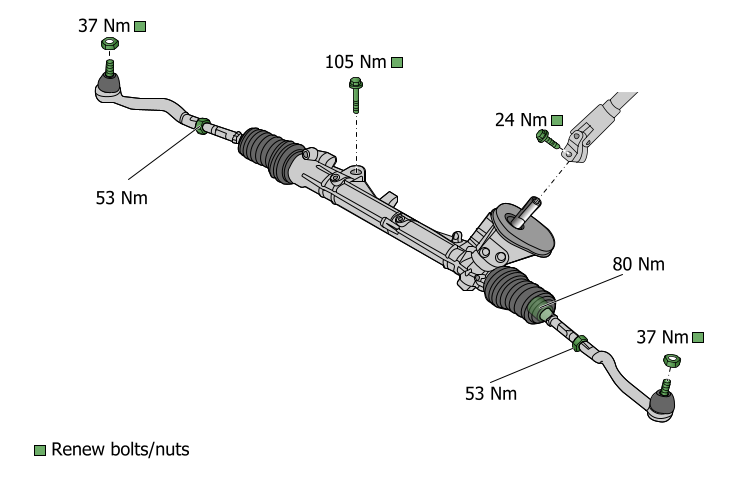

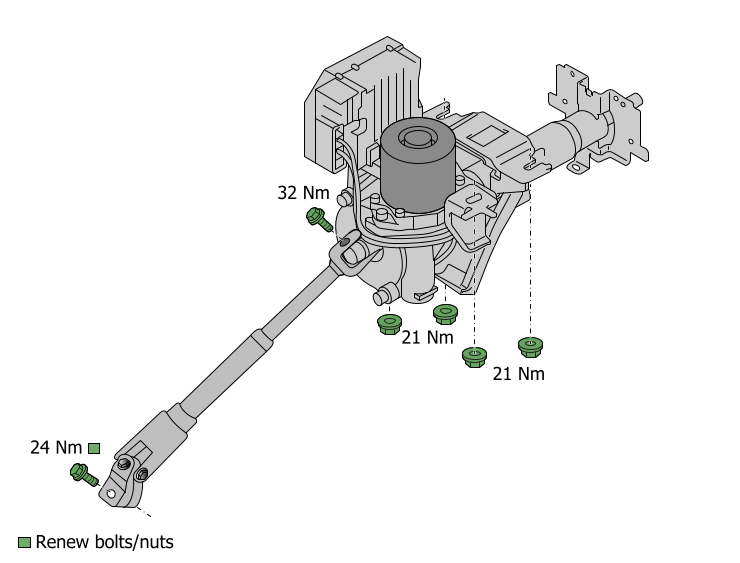

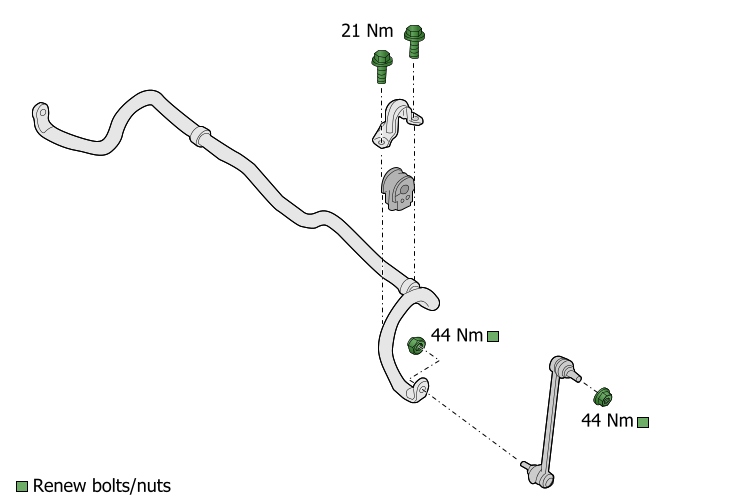

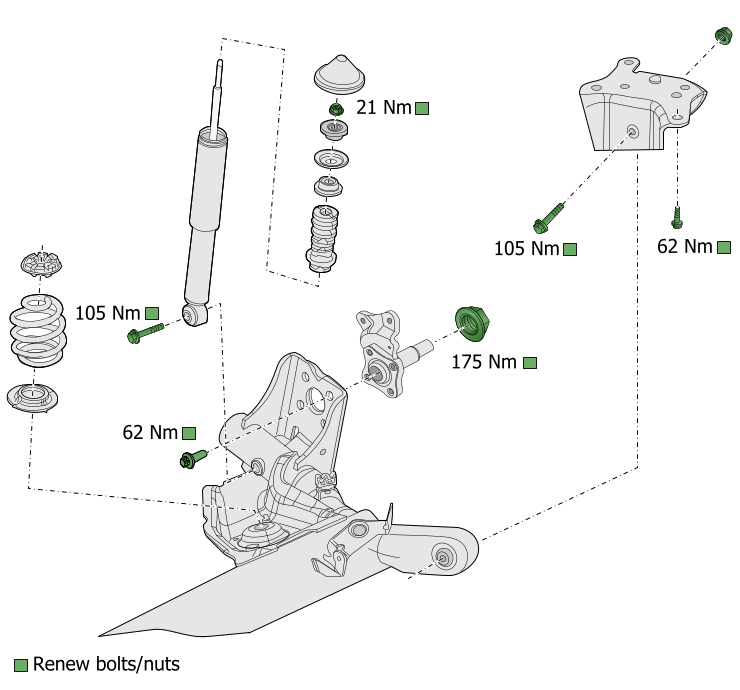

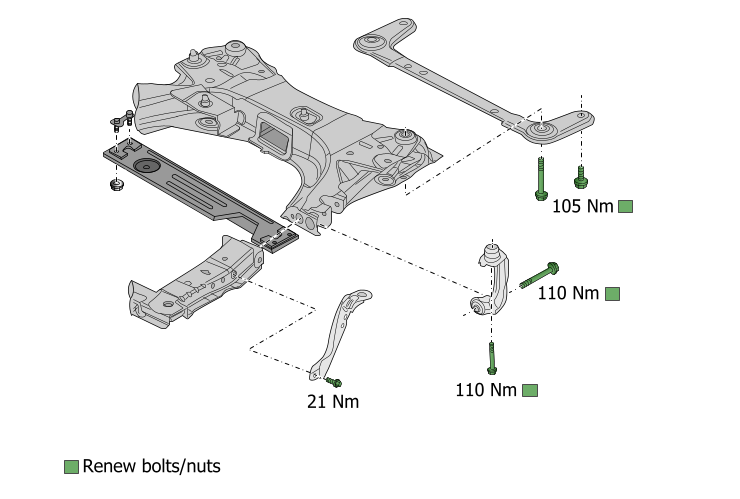

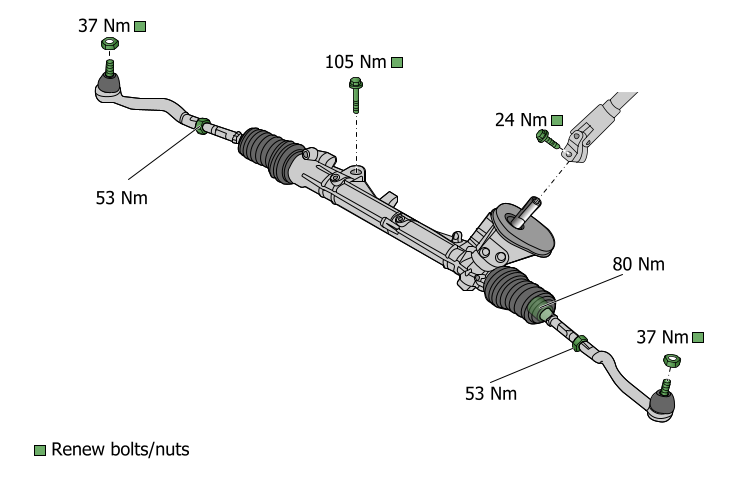

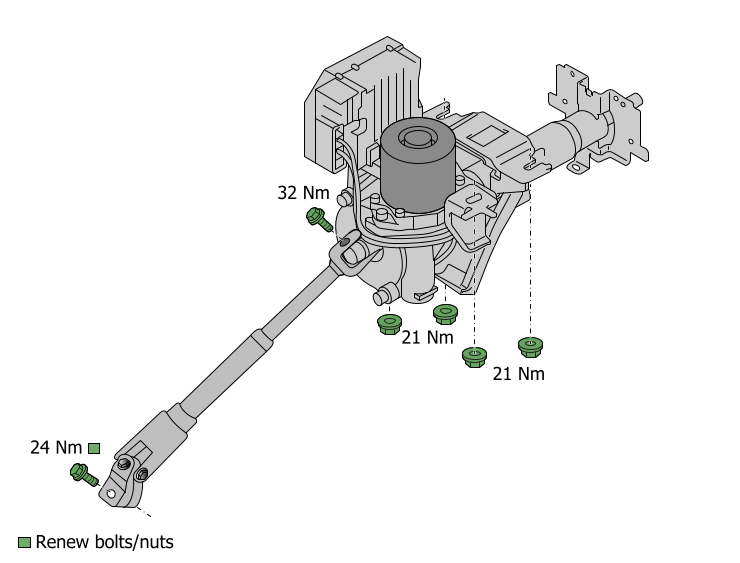

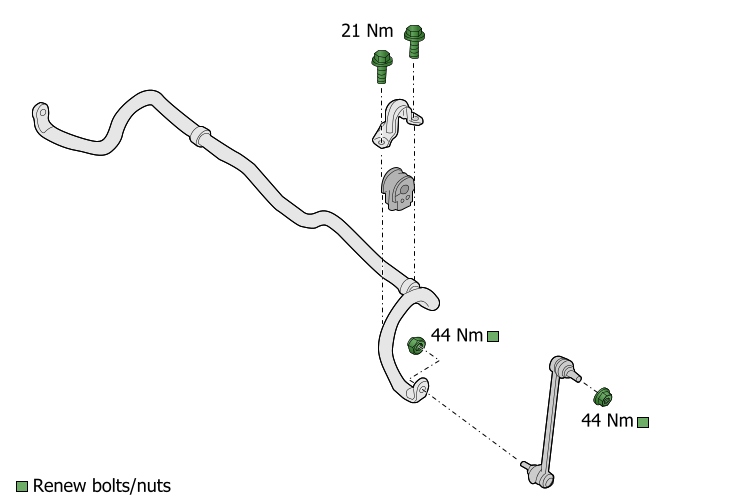

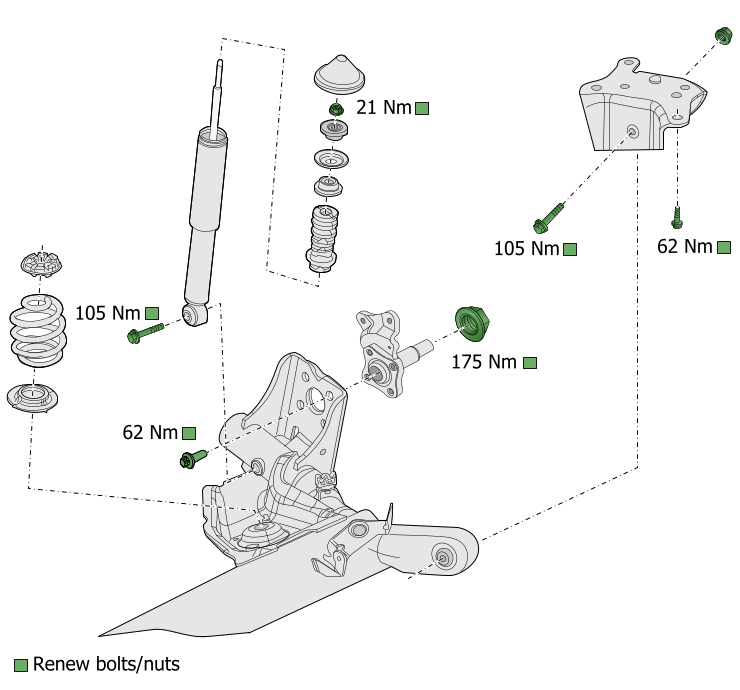

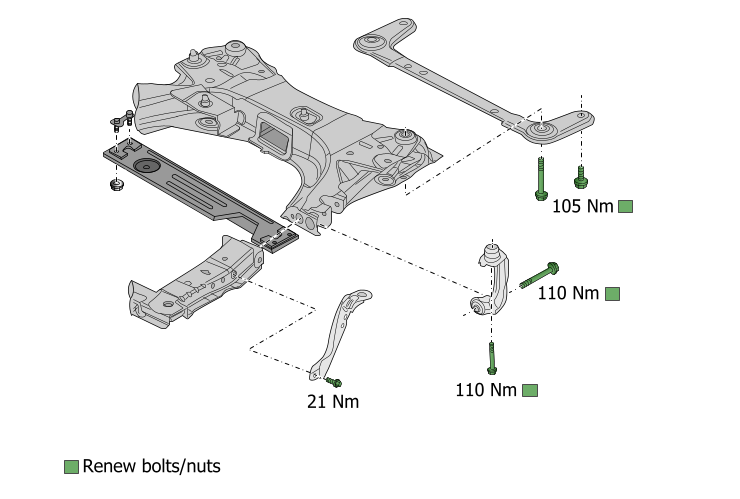

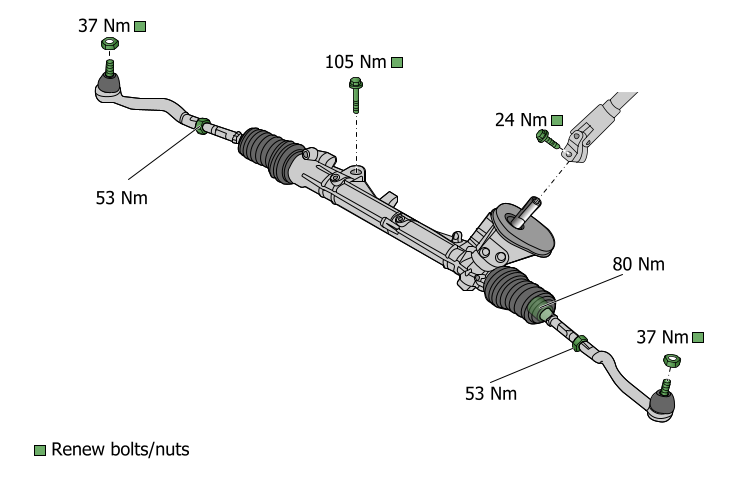

| Suspension: Refer to 'Technical drawings' | |

| Wheels and tyres | |

| Wheel bolts | |

| (Clean the contact surfaces and wheel bolts/nuts; lightly grease the wheel centre taper only but do not grease the wheel bolts/nuts) | |

| (Caution! Do not use power tools when screwing in or tightening wheel nuts/bolts) | |

| Stage 1 | 30 (Nm) |

| Stage 2 (Rotate the wheel by 180°) | |

| Stage 3 | 140 (Nm) |

| OE Wheel fitment Information | |

| General Information | |

| Loosen the wheel bolts with the wheel on the ground. | |

| Use sockets with protective sheaths in order to avoid scratching the alloy wheel rims. | |

| Clean the hub carrier using a wire brush. | |

| Coat the wheel mating face with COPPER ANTISEIZURE GREASE. | |

| Pretighten the wheel bolts to 30 N. | |

| m , with the wheel suspended. | |

| Torque tighten the wheel bolts in order to correct torque. | |

| Important Information | |

| There are two types of wheel bolts, do not swap them. | |

| Do not strike the surface of the wheel using excessive force as this may damage. | |

| Steering | |

| Note: Always renew stretch bolts and self-locking nuts | |

| Steering wheel | 44 (Nm) |

| Engine | |

| Engine sump, including filter | 5.4 (l) |

| Cooling system | 5.0 (l) |

| Brakes : General data | |

| Brake system | 1.0 (l) |

| Manual transmission, TL4, 6-speed | |

| Manual transmission | |

| Gearbox refill | 2.0 (l) |

| Plug location (Drain plug) | |

| Plug location (Filler plug) | |

| Air conditioning | |

| Air conditioning | |

| Plug location (High-pressure connecting pipe (H); low-pressure connecting pipe (L)) | |

| Refrigerant | 510 ± 35 (g) |

| Air-conditioning compressor oil, system total | 150 ± 10 (ml) |

| Air-conditioning condenser (only when renewed), additional capacity (Quantity of oil recovered plus specified top-up) | 30 (ml) |

| Air-conditioning receiver/dryer (only when renewed), additional capacity (Quantity of oil recovered plus specified top-up) | 15 (ml) |

| Air-conditioning evaporator (only when renewed), additional capacity (Quantity of oil recovered plus specified top-up) | 30 (ml) |

| Each air-conditioning hose, additional capacity (Quantity of oil recovered plus specified top-up) |

| Suspension | |

| Wheelbase (Hatchback) | 2451 (mm) |

| Wheelbase (Estate) | 2575 (mm) |

| Vehicle condition (Unloaded) | |

| Ride height, front (Sport suspension) | A= 143 - 169 (mm) |

| Ride height, front (Vehicles with Sports package) | A= 134 - 155 (mm) |

| Ride height, rear (Sport suspension) | B= 241 - 273 (mm) |

| Ride height, rear (Vehicles with Sports package) | B= 233 - 258 (mm) |

| Toe-out, front | 0°00' ± 0°10' (°) |

| Camber, front | 0°00' ± 0°60' (°) |

| Maximum difference between the left-hand side and right-hand side | 0°30' (°) |

| Castor, front | 4°30' ± 0°60' (°) |

| Maximum difference between the left-hand side and right-hand side | 0°30' (°) |

| King pin inclination (KPI), front | 9°40' ± 0°35' (°) |

| Maximum difference between the left-hand side and right-hand side | 0°30' (°) |

| Toe-in, rear (Sport suspension) | 0°10' ± 0°08' (°) |

| Toe-in, rear (Vehicles with Sports package) | 0°12' ± 0°12' (°) |

| Camber, rear | -1°33' ± 0°20' (°) |

| Suspension : General data | |

| Wheelbase | 2585 (mm) |

| Front disc brakes | |

| Disc diameter, front | 312.0 (mm) |

| Disc thickness, front | 28.0 (mm) |

| Disc thickness, front, minimum | 26.0 (mm) |

| Brake pad thickness, front (Including backplate) | 17.4 (mm) |

| Brake pad thickness, front, minimum (Including backplate) | 8.0 (mm) |

| Disc run-out, maximum | 0.07 (mm) |

| Rear disc brakes | |

| Disc diameter, rear | 274.0 (mm) |

| Disc thickness, rear | 11.0 (mm) |

| Disc thickness, rear, minimum | 9.5 (mm) |

| Brake pad thickness, rear (Including backplate) | 15.8 (mm) |

| Brake pad thickness, rear, minimum (Including backplate) | 7.5 (mm) |

| Disc run-out, maximum | 0.07 (mm) |

| Engine | |

| Cap pressure (Brown cap) | 1.2 (bar) |

| Cap pressure (Yellow cap) | 1.4 (bar) |

| Cap pressure (White cap) | 1.6 (bar) |

| Cap pressure (Grey cap) | 1.8 (bar) |

| Thermostat opening temperature | 75 (°C) |

| Thermostat fully open | 87 (°C) |

| Engine | |

| Idle speed, minimum | 750 (rpm) |

| Idle speed, maximum | 850 (rpm) |

| CO exhaust gas (At idle speed) | < 0.5 (%) |

| Fast-idle speed | 2500 - 3000 (rpm) |

| CO at fast-idle speed | < 0.3 (%) |

| Oil temperature during test | 80 (°C) |

| Lambda (At fast-idle speed) | 0.97-1.03 |

| Lambda change (Delta Lambda) | 0.03 |

| Manual transmission, EURO 4, Hatchback (Europe) | |

| Fuel consumption, combined usage | 8.40 - 8.90 (l/100 km) |

| Fuel consumption, extra-urban driving | 6.50 - 7.10 (l/100 km) |

| Fuel consumption, urban driving | 11.60 - 12.20 (l/100 km) |

| Emission code | Euro 4 |

| Emission standard | 70/220*2003/76B (2006-03-14 ->) |

| CO2 average | 199 - 209 (g/km) |

| CO | 0.907 (g/km) |

| HC | 0.082 (g/km) |

| NOx | 0.079 (g/km) |

| HC NOx | - |

| Engine | |

| Engine management (make and type) | Siemens Sirius 34 |

| Firing order | 1 - 3 - 4 - 2 |

| Ignition coil primary resistance | 0.5 (ohms) |

| Ignition coil secondary resistance | 10000 - 12000 (ohms) |

| Valve clearance | |

| Hydraulic | |

| Idle speed | 800 ± 50 (rpm) |

| Fuel pump pressure | 3.3 - 3.7 (bar) |

| Spark plugs (make and type) | NGK PFR7Z-TG |

| Spark plug gap | 0.8 - 0.9 (mm) |

| Spark plugs (make and type) | CHAMPION |

| Spark plug gap | 0.85 - 0.95 (mm) |

| Number of spark plugs | 4 |

| Oil pressure at idle speed (at 80 °C) | 0.8 (bar) |

| Oil pressure (at 80 °C) | 3.7 - 5.3 / 4000 (bar/rpm) |

| Maximum cylinder head distortion | 0.05 (mm) |

| Drive belt layout |

Very useful! could do with being pinned somewhere

| Stage 2 | 50 - 70 (°) |

| Stage 2 | 58 - 66 (°) |

| Symptom |

| Broken oil filter |

| Cause |

| Faulty oil pump |

| Solutions |

| Run the engine at 3000 rpm |

| Check the oil pressure |

| Expected value: 3 bar |

| Action required if the value is too high: > 6 bar |

| Renew the oil pump |

| Symptom |

| The boot lid releases when door unlocking is activated |

| Cause |

| Faulty boot lid control button |

| Solutions |

| Renew the boot lid control button |

| Symptom |

| After turning the ignition on: |

| The dipped beam comes on and remains on |

| Main beam malfunction |

| Front wiper/washer malfunction |

| Rear wiper malfunction |

| Cause |

| Damaged wiring |

| Solutions |

| Check the wiring condition between the following components: |

| Light stalk switch |

| Wiper stalk switch |

| Repair the wiring |

| If necessary: |

| Renew the light stalk switch |

| Symptom |

| Clicking noise from the engine compartment |

| Location: |

| Cylinder head |

| Cause |

| Inlet camshaft: |

| Faulty camshaft timing actuator |

| Solutions |

| Inlet camshaft: |

| Renew the camshaft timing actuator |

| Symptom |

| Inoperative windscreen wipers |

| Note: The symptom is intermittent |

| Cause |

| Water ingress into the windscreen wiper motor |

| Solutions |

| Connect the diagnostic tool |

| Check the windscreen wiper parameters |

| If a fault is found, renew the windscreen wiper motor |

| Symptom |

| Horn failure |

| Windscreen washer failure |

| Cause |

| Poor contact between the stalk switches and the connector |

| Solutions |

| Wiper stalk switch: |

| Check the connector for damage and correct fitting |

| Check the connector pins |

| Renew or repair the connector if necessary |

| Clean the electrical connectors and allow to dry |