You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tom's Track Car - BMW E46 -Engine Number 3

- Thread starter tombate911

- Start date

tombate911

Paid Member

Soo back to an update... This time I'll keep it a bit smaller and document the progress.

At the end of the last big post I said about the stiction in the rear end I noticed properly when lifting it up on the ramp, don't always get the full effect jacking up one side of the car due to the tension in the ARB. Decided it was something I was going to tackle to free up the suspension travel in the rear end to hopefully let the wheels track the ground a little better and stop it lifting the inside wheel in some corners as the damper can extend with less resistance as well as trying to reduce the little bit of wheel hop I get from the rear end which I think it down to deflection in the polybushes as it was improved when I upped the preload on the subframe bushes last year. That's my rational anyway for the following changes so we'll see how we get on.

First job on the cards is to drop the rear end off the car. Starting with the ARB, driveshafts, diff and brace. Camber arms also pulled off and these are going to be completed remade with bushes for the inner joint rather than a polybush.

Dropped the rear arms off the car. When I built the car I did fit two ball joints to the upper and lower mounts in the rear trailing arms the same as fitted on the M3's

Dropped the subframe off with the upper arms in place, nice to see the powder coating is still looking good 3 years on from building it originally, just a film of dirt all over it, will give it a good wash before refitting.

Pushed out the the poly bushes out from the suspension, at this point I decided while it was all off and fitting ball joints to the 3 rear arms... trailing arms, upper arms and lower arms, that I would do what I did for a friend a year or so ago which was make solid mounts for the subframe as well as the diff to stiffen up the rear end as well as raising the subframe as much as possible to give a little bit of roll centre correction while I am at it, Jordan has been running a set of bushes I made for him two years ago with great success so why not do the same on my own car.

First job in the process of making the bushes for the solid mounts was to order some 3" round aluminium. This then became an evening job I have been chipping away at in the evenings, here I've got the material mounted and supported on the lathe. Starting to face off the material and parallel turn it to the correct diameter.

Using the lathe I roughed out the diameters of the bushes on the material and parted of the majority of the way through the material before removing it from the machine and finishing the last bit of the cut with a saw.

To finish them off it was a case of drilling holes through the middle, finishing off the diameters to specification adding chamfers. I spent a lot of time measuring the subframe and the underside of the boot floor and designed each bush to move the subframe up, clear the factory subframe studs as well as still be able to use the E46 brace fitted to the front of the subframe

While I was working on making all the solid subframe bushes I did get delivery of the VAC Motorsport upper arm bushes. These are nice and simple aluminium sleeves with a rose joint in the middle held in by a circlip. I was originally going to make these myself but in the end with the money saved on making all the other bits I thought I would buy the mounts for the upper arms and the RTAB.

I cracked on last week and got the rest of the mounts machined and finished.

The photo consists of:

4 Subframe mounts

2 Front diff bushes

1 Rear diff bush

2 Vac upper arm inner

2 Steel CDS rings which I have machined to the correct diameter for the ball joints front left which will be welded to the camber arms to replace the inner camber arm poly bush

I am just waiting on the final piece to the puzzle which is a pair of Millway solid rear trailing arm bushes to finish off the solid rear end.

Fitting the diff bushes was a little more awkward as the solid bushes require a lot more force to fit, I tried to get it mounted in the hydraulic press but wasn't able to get the correct angle due to the ARB mounts so opted for the more simple big bolt and a long bar to pull them in.

Subframe mounts were a lot easier to get into the press so they were pressed in without issue. This is a top view looking at the top of the subframe, you'll notice the bushes don't have a top hat the same way the poly bushes do, this has enabled me to bring the subframe right up to the boot floor to get some roll centre correction.

Quick test of the subframe on the car to check for clearance. Looking good so far but we will be 100% sure when all the driveline is connected back together with diff, prop and drive shafts. Little bit of mud still lurking around the rear end of the car from my off last year at Oulton, will be getting the jet wash out to clean all the rear end up, wire wheeling back some of the boot floor and repainting/stone chipping some areas while it's all off again. The original spring seats are looking a bit untidy and want to clean up and paint the trailing arms pockets.

Last job this week has been fitting the VAC Bearings into the inner of the upper spring arms. Nice simple design which was pressed in easily with the hydraulic press and secured with a circlip on the other side to prevent any movement.

Once I've finished tidying up the rear end with some paint I will start to build it back up and have some more photos from that soon. Will come back with another update soon.

At the end of the last big post I said about the stiction in the rear end I noticed properly when lifting it up on the ramp, don't always get the full effect jacking up one side of the car due to the tension in the ARB. Decided it was something I was going to tackle to free up the suspension travel in the rear end to hopefully let the wheels track the ground a little better and stop it lifting the inside wheel in some corners as the damper can extend with less resistance as well as trying to reduce the little bit of wheel hop I get from the rear end which I think it down to deflection in the polybushes as it was improved when I upped the preload on the subframe bushes last year. That's my rational anyway for the following changes so we'll see how we get on.

First job on the cards is to drop the rear end off the car. Starting with the ARB, driveshafts, diff and brace. Camber arms also pulled off and these are going to be completed remade with bushes for the inner joint rather than a polybush.

Dropped the rear arms off the car. When I built the car I did fit two ball joints to the upper and lower mounts in the rear trailing arms the same as fitted on the M3's

Dropped the subframe off with the upper arms in place, nice to see the powder coating is still looking good 3 years on from building it originally, just a film of dirt all over it, will give it a good wash before refitting.

Pushed out the the poly bushes out from the suspension, at this point I decided while it was all off and fitting ball joints to the 3 rear arms... trailing arms, upper arms and lower arms, that I would do what I did for a friend a year or so ago which was make solid mounts for the subframe as well as the diff to stiffen up the rear end as well as raising the subframe as much as possible to give a little bit of roll centre correction while I am at it, Jordan has been running a set of bushes I made for him two years ago with great success so why not do the same on my own car.

First job in the process of making the bushes for the solid mounts was to order some 3" round aluminium. This then became an evening job I have been chipping away at in the evenings, here I've got the material mounted and supported on the lathe. Starting to face off the material and parallel turn it to the correct diameter.

Using the lathe I roughed out the diameters of the bushes on the material and parted of the majority of the way through the material before removing it from the machine and finishing the last bit of the cut with a saw.

To finish them off it was a case of drilling holes through the middle, finishing off the diameters to specification adding chamfers. I spent a lot of time measuring the subframe and the underside of the boot floor and designed each bush to move the subframe up, clear the factory subframe studs as well as still be able to use the E46 brace fitted to the front of the subframe

While I was working on making all the solid subframe bushes I did get delivery of the VAC Motorsport upper arm bushes. These are nice and simple aluminium sleeves with a rose joint in the middle held in by a circlip. I was originally going to make these myself but in the end with the money saved on making all the other bits I thought I would buy the mounts for the upper arms and the RTAB.

I cracked on last week and got the rest of the mounts machined and finished.

The photo consists of:

4 Subframe mounts

2 Front diff bushes

1 Rear diff bush

2 Vac upper arm inner

2 Steel CDS rings which I have machined to the correct diameter for the ball joints front left which will be welded to the camber arms to replace the inner camber arm poly bush

I am just waiting on the final piece to the puzzle which is a pair of Millway solid rear trailing arm bushes to finish off the solid rear end.

Fitting the diff bushes was a little more awkward as the solid bushes require a lot more force to fit, I tried to get it mounted in the hydraulic press but wasn't able to get the correct angle due to the ARB mounts so opted for the more simple big bolt and a long bar to pull them in.

Subframe mounts were a lot easier to get into the press so they were pressed in without issue. This is a top view looking at the top of the subframe, you'll notice the bushes don't have a top hat the same way the poly bushes do, this has enabled me to bring the subframe right up to the boot floor to get some roll centre correction.

Quick test of the subframe on the car to check for clearance. Looking good so far but we will be 100% sure when all the driveline is connected back together with diff, prop and drive shafts. Little bit of mud still lurking around the rear end of the car from my off last year at Oulton, will be getting the jet wash out to clean all the rear end up, wire wheeling back some of the boot floor and repainting/stone chipping some areas while it's all off again. The original spring seats are looking a bit untidy and want to clean up and paint the trailing arms pockets.

Last job this week has been fitting the VAC Bearings into the inner of the upper spring arms. Nice simple design which was pressed in easily with the hydraulic press and secured with a circlip on the other side to prevent any movement.

Once I've finished tidying up the rear end with some paint I will start to build it back up and have some more photos from that soon. Will come back with another update soon.

suj

Paid Member

Great work as usual Tom, I would love access to a lathe (and I don't also...as i'd end up there all the time haha).

Have you consider true rear coilovers then doing away with the top arm? I run HSDs (came on the car) and they offer a conversion to change to true rears, means you then have access to many linear spring rates (than being limited by manufacturers of non-linear seperate springs), also you could get a spring perch-less arm to save weight too I guess.

Have you consider true rear coilovers then doing away with the top arm? I run HSDs (came on the car) and they offer a conversion to change to true rears, means you then have access to many linear spring rates (than being limited by manufacturers of non-linear seperate springs), also you could get a spring perch-less arm to save weight too I guess.

tombate911

Paid Member

Great work as usual Tom, I would love access to a lathe (and I don't also...as i'd end up there all the time haha).

Have you consider true rear coilovers then doing away with the top arm? I run HSDs (came on the car) and they offer a conversion to change to true rears, means you then have access to many linear spring rates (than being limited by manufacturers of non-linear seperate springs), also you could get a spring perch-less arm to save weight too I guess.

I do actually run a true rear coilover. I have done the strengthening of the strut tops and rear brace between the strut tops to suit running a true rear coilover. I have considered going to another after market rear arm but the cost vs reward didn't seem worth it and I just went for the VAC inner arms, at one point I was going to make my own upper arms with adjustable width so the whole trailing arm could be brought in and out but decided to keep it simple. Nice and simple to swap the springs out, I have had a mess with different spring rates and have settled with a softer rear spring for the moment.

Amazing Tom. Making your own parts must be so rewarding. Love this thread

Yeah @Big Ben @suj the ability to manufacture parts is a big part of the hobby. Nice to have items on there that you'd put some thought and effort into designing and making too. Glad you enjoy the thread guys. Comments like that keep me updating the thread. I stopped posting on here for a while until someone messaged me on Instagram asking for an update, so it must be well received.

suj

Paid Member

I do actually run a true rear coilover. I have done the strengthening of the strut tops and rear brace between the strut tops to suit running a true rear coilover. I have considered going to another after market rear arm but the cost vs reward didn't seem worth it and I just went for the VAC inner arms, at one point I was going to make my own upper arms with adjustable width so the whole trailing arm could be brought in and out but decided to keep it simple. Nice and simple to swap the springs out, I have had a mess with different spring rates and have settled with a softer rear spring for the moment.

Yeah @Big Ben @suj the ability to manufacture parts is a big part of the hobby. Nice to have items on there that you'd put some thought and effort into designing and making too. Glad you enjoy the thread guys. Comments like that keep me updating the thread. I stopped posting on here for a while until someone messaged me on Instagram asking for an update, so it must be well received.

Ah you run Gaz Golds, sorry I was getting confused with someone else (follow too many BMW track cars over forums haha).

Reason I asked, as I was eyeing up those VAC Upper control arm bushes, I run VAC rear camber arms and quality is amazing, but for the price of them, for a bit more you can get these

Adjustable Upper Camber Arms BMW E36 E46 Z4 - Uniball (Black)

PMC Motorsport Steel Adjustable Upper Control Arms for BMW E36 E46 Z4 with Fluro Uniball (Black)

A few friends have run PMC items (shifters and camber arms) and I was really impressed with their quality to be honest.

Definitely keep updating mate, there's many people who don't comment (like myself, I never commented but loved the updates).

I love making stuff myself too, but I have zero facilities (well just a 3d printer lol), so I love seeing your work.

tombate911

Paid Member

Finishing off the rear end - Cadwell Park Prep

At the end of the last update I was waiting on the rear trailing arm bearings to arrive. Millway had to manufacture them so it took 4 weeks for them to arrive but worth the wait for them

Pressed into the rear arms

The final rubber bushing that I wanted to replace was for the inner camber arms but there wasn't anything available off the shelf to go into the camber arms I was running, I could have bought some expensive off the shelf replacement arms with spherical bearings in them but opted to modify the inner of the arms to run a standard ball joint which I use in the upper and lower trailing arm bushes.

I machined some CDS tubing to the correct inner diameter to be able to press in one of the OEM BMW M3 ball joints. welded it to the camber arm with some triangulation material

This obviously removed the left hand thread from the camber arm so something was needed to be able to give fine adjustment of the camber.

So I got a set of these made up with M18 threaded bar so the length of the camber arm can be adjusted and also slots made to use the standard camber bolts for fine adjustment when doing alignment.

Subframe all built up with solid bushes

When bolting the rear end back together I gave the centre prop bearing a once over and the rubber was tearing, luckily I checked this as it was very close to failing. Destroyed it removing it from the prop

Replaced with a brand new bearing and reassembled the prop after marking it before disassembly

Onto then bolting the whole of the rear end back together. Rear arms all fitted with camber bolts in the camber arms

Diff and drive shafts all put back together. Photo shows the solid bushes in the subframe and the diff mounting

Small test of the rear end, the rear wheels moving through their travel without binding up from stiction from the polybushes. This was the aim for rebuilding the rear end to enable to suspension to be able to work as effectively as possible and keep the tyres on the floor as much as possible and let the wheels follow the contours of the ground more efficiently. Cadwell Park will be a great test for this next week. Eagle eyed readers will probably notice the NSR tyre is mounted on the OSR. After doing two days on track I'm going to rotate the tyres from left to right side of the car to keep the tyre wear as uniform as possible across the tyres.

And finally to bring it all together it was back out with the string kit and alignment tables and did the rear alignment back to the same specification as Anglesey when it drove perfectly

Few things to finish off over the next few days, clearing cameras, setting up the data logger and loading the van and trailer but we're ready to go to Cadwell Park on Wednesday and then Snetterton the following week. Looking forward to getting behind the wheel of it again.

At the end of the last update I was waiting on the rear trailing arm bearings to arrive. Millway had to manufacture them so it took 4 weeks for them to arrive but worth the wait for them

Pressed into the rear arms

The final rubber bushing that I wanted to replace was for the inner camber arms but there wasn't anything available off the shelf to go into the camber arms I was running, I could have bought some expensive off the shelf replacement arms with spherical bearings in them but opted to modify the inner of the arms to run a standard ball joint which I use in the upper and lower trailing arm bushes.

I machined some CDS tubing to the correct inner diameter to be able to press in one of the OEM BMW M3 ball joints. welded it to the camber arm with some triangulation material

This obviously removed the left hand thread from the camber arm so something was needed to be able to give fine adjustment of the camber.

So I got a set of these made up with M18 threaded bar so the length of the camber arm can be adjusted and also slots made to use the standard camber bolts for fine adjustment when doing alignment.

Subframe all built up with solid bushes

When bolting the rear end back together I gave the centre prop bearing a once over and the rubber was tearing, luckily I checked this as it was very close to failing. Destroyed it removing it from the prop

Replaced with a brand new bearing and reassembled the prop after marking it before disassembly

Onto then bolting the whole of the rear end back together. Rear arms all fitted with camber bolts in the camber arms

Diff and drive shafts all put back together. Photo shows the solid bushes in the subframe and the diff mounting

Small test of the rear end, the rear wheels moving through their travel without binding up from stiction from the polybushes. This was the aim for rebuilding the rear end to enable to suspension to be able to work as effectively as possible and keep the tyres on the floor as much as possible and let the wheels follow the contours of the ground more efficiently. Cadwell Park will be a great test for this next week. Eagle eyed readers will probably notice the NSR tyre is mounted on the OSR. After doing two days on track I'm going to rotate the tyres from left to right side of the car to keep the tyre wear as uniform as possible across the tyres.

And finally to bring it all together it was back out with the string kit and alignment tables and did the rear alignment back to the same specification as Anglesey when it drove perfectly

Few things to finish off over the next few days, clearing cameras, setting up the data logger and loading the van and trailer but we're ready to go to Cadwell Park on Wednesday and then Snetterton the following week. Looking forward to getting behind the wheel of it again.

Helpimonfire

Paid Member

Cracking update as usual Tom! Looking forward to being overtaken by this at Snetterton

tombate911

Paid Member

Cadwell August 2021 -

Update to follow but here's a video of a couple of laps for the moment...

Update to follow but here's a video of a couple of laps for the moment...

tombate911

Paid Member

Wednesday morning Cadwell Park.

Cadwell is a fair old 3+ hour drive for us from the Northwest so we now have a habit of booking a hotel in Louth so it's only a ten minute drive in the morning to get to the circuit.

Cooked breakfast in the hotel to start the day and we were at the circuit before 8 clock.

I had set everything up prior to putting the car on the trailer with cold tyre pressures and damper settings so it was purely a case of rolling it off the trailer and signing on.

Sighting laps went off without any issues and I was straight out on track as soon as the track opened. Not my usual style but I was ready to go and wanted to take a friend who was on his 3rd ever track day and 1st time as Cadwell park for a quick morning session to show him the lines and some tips around the circuit for his first session.

The car felt perfect, the changes to the rear end feeling noticeably more predictable with the tyres staying in contact with the ground given much better drive out of off camber corners.

I did a nice 15 minute stint getting some heat into the car and popped back into the pits to go out as a passenger in his mini and give a few pointers.

Managed to then get a few sessions in on my own and find some reasonable laps with a little bit of traffic. The day was interrupted a little bit with red flags due to the floppies ending up on the circuit and them having to red flag a few sessions to replace them. The car felt so much better than this time last year, change of tyres and a little more aero with the help of the rear wing and the car had noticeably more grip and was far more planted through the corners.

Not long before lunchtime my stomach would catch up with me though, for some reason I've always struggled with sickness at Cadwell. No where else not even Spa. But just before lunch as the car was getting really hot inside I did a little bit of dry heaving driving through hall bends which resulted in a trip to the toilets, some water and some paracetamol. I've often felt sick at Cadwell but never physically been sick but he heat inside the car today was terrible. I dropped the window a couple of inch by taking off the door card and phyiscally lowering it and change from a long sleeve to a short sleeve top ready for the afternoon.

Quick check the logger and cameras were all working fine in the heat and we're ready to go out again.

The afternoon sessions where brilliant, nice an quiet with only light traffic on the laps. Managed to do a few sessions chasing some quicker cars, some of them you've seen me post about before. Jordans E36 and Nigels Pinderwagon. Will finish off the video from the afternoon and post it up afterwards.

The second to last session I managed to get 3 nice clear laps without anyone holding me up. At the time due to the heat and still feeling a little sick I was just focusing on driving smooth not chasing lap times but managed to post some consistent 1:42's. Nicely 2.5 seconds quicker than my best lap times last year. Still lots of time to be found around the circuit as my cornering speeds are still way lower than they should be with the car set up now but it's improving all the time.

I did notice in this session with some clear track on the straights I was looking at the temperatures, oil and fuel pressure, oil pressure seemed a little bit low on the back straight. At the time I made a mental note of a 30-40psi oil pressure and carried out... Continues later...

Completed it. Another fantastic flawless track day at Cadwell Park in prime conditions once again. Time to pack up the car and trailer and head into Louth for a couple of drinks and an indian before driving back home the new day to get sorted for Snetterton.

Reviewing the track day - Data, Data, Data

After the track day I do my usual editing of videos and checking all of the data from the logs. The data logger logs a lot more information than shown on the videos but I when looking at the oil pressure logs I did confirm what I saw when I was out on track was that the engine was only doing high 30's to 40 PSI hot at high RPM.

Looking back at previous logs the car normally runs at 55-60psi Hot at higher RPM. Thought it was a little strange but I checked the oil pressure when It had been left over night and the oil was cold. Started the car and initial oil pressure was 60psi. No trouble I thought until the engine oil got hot again and it settled at 18psi idle which is normal but when reving the engine the highest oil pressure I could get was 40psi. 20psi lower than expected.

I decided to dig deeper into it this morning, despite the fact we set off for Snetterton in two days.

I assumed it was going to be something to do with the oil relief spring or similar. Time to get the sump off and have a look.

It's not the easiest of jobs to get to the oil pump. but when the sump was dropped the problem was obvious straight away and it wasn't what we expected at all...

initial observations shows that the bolts that hold the two sections of the oil pump have backed out, no wonder it was showing lower oil pressure as it was being pumped back into the sump rather than up into the main gallery of the engine.

Second observation, despite my efforts when I built this engine of lock wiring the VAC Motorsport ARP bolt to the gear as this previously has come undone in the past despite the VAC kit being an upgrade for the known weak OEM oil pump shaft, The wire was still holding the ARP tight however the gear has been wearing on the oil pump shaft. This is the second one to do this.

2021

2020

This engine has only ran for 5 full days since it was completely rebuilt so there is something I need to address with this oil pump issue on the M54's. I will come back to this topic later on.

The main priority at the moment is to get the car to be able to work for Snetterton and then address the issues afterwards.

I still had the OEM oil pump shaft in the garage and a friend has a spare gear from an E36 that I could run on it to get me through the next week. However the OEM shafts have a left hand thread nut on them which are known for coming undone and causing zero oil pressure.

I decided the best I could do with leaving to go away in 48 hours was to drill the standard nut and lockwire it on.

Drilled two holes in the nut on both sides to lock wire in place.

Rebuilt the pump back up with high strength lock tight on the bolts and the nut, as well as adding stainless lock wire to the nut to try to prevent it from coming undone. Not the neatest wiring I have ever done but I wanted to make sure that the nut was under preload to try to prevent it from moving

Last job of the day today was to replace the crank pulley, I had a brand new Febi damper pulley on the shelf so I thought it was a good time to get it put on there while the car was in pieces. The old pulley was looking a little tired so hopefully this will help a little bit

Some fresh oil and many hours work today and the E46 is back running on axle stands, there's a few jobs to finish off tomorrow which is waiting on parts to arrive in the post but it should be ready to go onto the trailer tomorrow evening.

Oil pump future.

Keeping it short and sweet but here's a list of fixes for the future.

-To fix the oil pump issue I need to fix the harmonic issues with the crank which can only really be dampened with a better quality damper such as a super damper. These are the best part of £1000.

-The oil pump chain is looking a little bit slack so I'm going to replace the chain with a new one.

-While replacing the chain I am going to drill and thread the block to add in a change tensioner similar to those seen on the S50/S54 engines which are designed for revving higher.

-Will probably look at different oil pump kits which offer a more solid key between the shaft and the gear.

Update to follow tomorrow with the final jobs finished - We're getting closer to being ready for Snetterton now.

Finally another video from Cadwell Park.

Cadwell is a fair old 3+ hour drive for us from the Northwest so we now have a habit of booking a hotel in Louth so it's only a ten minute drive in the morning to get to the circuit.

Cooked breakfast in the hotel to start the day and we were at the circuit before 8 clock.

I had set everything up prior to putting the car on the trailer with cold tyre pressures and damper settings so it was purely a case of rolling it off the trailer and signing on.

Sighting laps went off without any issues and I was straight out on track as soon as the track opened. Not my usual style but I was ready to go and wanted to take a friend who was on his 3rd ever track day and 1st time as Cadwell park for a quick morning session to show him the lines and some tips around the circuit for his first session.

The car felt perfect, the changes to the rear end feeling noticeably more predictable with the tyres staying in contact with the ground given much better drive out of off camber corners.

I did a nice 15 minute stint getting some heat into the car and popped back into the pits to go out as a passenger in his mini and give a few pointers.

Managed to then get a few sessions in on my own and find some reasonable laps with a little bit of traffic. The day was interrupted a little bit with red flags due to the floppies ending up on the circuit and them having to red flag a few sessions to replace them. The car felt so much better than this time last year, change of tyres and a little more aero with the help of the rear wing and the car had noticeably more grip and was far more planted through the corners.

Not long before lunchtime my stomach would catch up with me though, for some reason I've always struggled with sickness at Cadwell. No where else not even Spa. But just before lunch as the car was getting really hot inside I did a little bit of dry heaving driving through hall bends which resulted in a trip to the toilets, some water and some paracetamol. I've often felt sick at Cadwell but never physically been sick but he heat inside the car today was terrible. I dropped the window a couple of inch by taking off the door card and phyiscally lowering it and change from a long sleeve to a short sleeve top ready for the afternoon.

Quick check the logger and cameras were all working fine in the heat and we're ready to go out again.

The afternoon sessions where brilliant, nice an quiet with only light traffic on the laps. Managed to do a few sessions chasing some quicker cars, some of them you've seen me post about before. Jordans E36 and Nigels Pinderwagon. Will finish off the video from the afternoon and post it up afterwards.

The second to last session I managed to get 3 nice clear laps without anyone holding me up. At the time due to the heat and still feeling a little sick I was just focusing on driving smooth not chasing lap times but managed to post some consistent 1:42's. Nicely 2.5 seconds quicker than my best lap times last year. Still lots of time to be found around the circuit as my cornering speeds are still way lower than they should be with the car set up now but it's improving all the time.

I did notice in this session with some clear track on the straights I was looking at the temperatures, oil and fuel pressure, oil pressure seemed a little bit low on the back straight. At the time I made a mental note of a 30-40psi oil pressure and carried out... Continues later...

Completed it. Another fantastic flawless track day at Cadwell Park in prime conditions once again. Time to pack up the car and trailer and head into Louth for a couple of drinks and an indian before driving back home the new day to get sorted for Snetterton.

Reviewing the track day - Data, Data, Data

After the track day I do my usual editing of videos and checking all of the data from the logs. The data logger logs a lot more information than shown on the videos but I when looking at the oil pressure logs I did confirm what I saw when I was out on track was that the engine was only doing high 30's to 40 PSI hot at high RPM.

Looking back at previous logs the car normally runs at 55-60psi Hot at higher RPM. Thought it was a little strange but I checked the oil pressure when It had been left over night and the oil was cold. Started the car and initial oil pressure was 60psi. No trouble I thought until the engine oil got hot again and it settled at 18psi idle which is normal but when reving the engine the highest oil pressure I could get was 40psi. 20psi lower than expected.

I decided to dig deeper into it this morning, despite the fact we set off for Snetterton in two days.

I assumed it was going to be something to do with the oil relief spring or similar. Time to get the sump off and have a look.

It's not the easiest of jobs to get to the oil pump. but when the sump was dropped the problem was obvious straight away and it wasn't what we expected at all...

initial observations shows that the bolts that hold the two sections of the oil pump have backed out, no wonder it was showing lower oil pressure as it was being pumped back into the sump rather than up into the main gallery of the engine.

Second observation, despite my efforts when I built this engine of lock wiring the VAC Motorsport ARP bolt to the gear as this previously has come undone in the past despite the VAC kit being an upgrade for the known weak OEM oil pump shaft, The wire was still holding the ARP tight however the gear has been wearing on the oil pump shaft. This is the second one to do this.

2021

2020

This engine has only ran for 5 full days since it was completely rebuilt so there is something I need to address with this oil pump issue on the M54's. I will come back to this topic later on.

The main priority at the moment is to get the car to be able to work for Snetterton and then address the issues afterwards.

I still had the OEM oil pump shaft in the garage and a friend has a spare gear from an E36 that I could run on it to get me through the next week. However the OEM shafts have a left hand thread nut on them which are known for coming undone and causing zero oil pressure.

I decided the best I could do with leaving to go away in 48 hours was to drill the standard nut and lockwire it on.

Drilled two holes in the nut on both sides to lock wire in place.

Rebuilt the pump back up with high strength lock tight on the bolts and the nut, as well as adding stainless lock wire to the nut to try to prevent it from coming undone. Not the neatest wiring I have ever done but I wanted to make sure that the nut was under preload to try to prevent it from moving

Last job of the day today was to replace the crank pulley, I had a brand new Febi damper pulley on the shelf so I thought it was a good time to get it put on there while the car was in pieces. The old pulley was looking a little tired so hopefully this will help a little bit

Some fresh oil and many hours work today and the E46 is back running on axle stands, there's a few jobs to finish off tomorrow which is waiting on parts to arrive in the post but it should be ready to go onto the trailer tomorrow evening.

Oil pump future.

Keeping it short and sweet but here's a list of fixes for the future.

-To fix the oil pump issue I need to fix the harmonic issues with the crank which can only really be dampened with a better quality damper such as a super damper. These are the best part of £1000.

-The oil pump chain is looking a little bit slack so I'm going to replace the chain with a new one.

-While replacing the chain I am going to drill and thread the block to add in a change tensioner similar to those seen on the S50/S54 engines which are designed for revving higher.

-Will probably look at different oil pump kits which offer a more solid key between the shaft and the gear.

Update to follow tomorrow with the final jobs finished - We're getting closer to being ready for Snetterton now.

Finally another video from Cadwell Park.

Last edited:

tombate911

Paid Member

Couple more photos from Cadwell Park, because why not!

Aside from the oil pump woes off the back of Cadwell Park I did manage to highlight one smaller issue from the additional grip from the modifications I've been working on recently.

Noticed that mid way through the morning I was getting more and more feedback through the wheel during braking. This normally occurs when there is some play in the suspension on the front end, normally a loose wishbone or worn out wheel bearing.

I had a check over the front end of the car and found this. The inner of the two piece polybush has popped forward, I took it off the car and popped it back in with a hammer and put it back on the car. it stayed put for a couple of sessions but popped back out later in the day, these bushes have been fine for years but I think the additional loading from the grip now is causing the bush to deflect and pop it's self out.

By the time I was home from Cadwell I only had the weekend until Tuesday to get sorted so I needed to find a replacement pretty quickly. I was originally looking to find a set of MRT Solid rose joint control arm mounts but unable to find any in the Uk which could deliver them for Tuesday so from a recommendation from Hack Motorsport the Condor Speed Shop mounts were recommended. These have a much smaller inner bush section which is made from a very hard polyurethane inside a new housing.

Compared with the OEM mounts with Polybush inserts

Looking forward to seeing what difference these make to the feel of the front end and hopefully is the end of the vibrations under braking with solid bushes.

Final few jobs for the day was to get the front end put back together, undertray and splitter and brake cooling ducts fitted, back on it's wheels and washed ready to leave for Snetterton at 9am in the morning.

I forgot to take a picture of it on it's wheels so this will have to do...

All sorted and loaded on the trailer now, looking forward to catching up with everyone on Thursday.

Aside from the oil pump woes off the back of Cadwell Park I did manage to highlight one smaller issue from the additional grip from the modifications I've been working on recently.

Noticed that mid way through the morning I was getting more and more feedback through the wheel during braking. This normally occurs when there is some play in the suspension on the front end, normally a loose wishbone or worn out wheel bearing.

I had a check over the front end of the car and found this. The inner of the two piece polybush has popped forward, I took it off the car and popped it back in with a hammer and put it back on the car. it stayed put for a couple of sessions but popped back out later in the day, these bushes have been fine for years but I think the additional loading from the grip now is causing the bush to deflect and pop it's self out.

By the time I was home from Cadwell I only had the weekend until Tuesday to get sorted so I needed to find a replacement pretty quickly. I was originally looking to find a set of MRT Solid rose joint control arm mounts but unable to find any in the Uk which could deliver them for Tuesday so from a recommendation from Hack Motorsport the Condor Speed Shop mounts were recommended. These have a much smaller inner bush section which is made from a very hard polyurethane inside a new housing.

Compared with the OEM mounts with Polybush inserts

Looking forward to seeing what difference these make to the feel of the front end and hopefully is the end of the vibrations under braking with solid bushes.

Final few jobs for the day was to get the front end put back together, undertray and splitter and brake cooling ducts fitted, back on it's wheels and washed ready to leave for Snetterton at 9am in the morning.

I forgot to take a picture of it on it's wheels so this will have to do...

All sorted and loaded on the trailer now, looking forward to catching up with everyone on Thursday.

Helpimonfire

Paid Member

Those P-bushes or whatever people call them have ALWAYS been a weak spot of all BMWs! Be interesting to see what the upgrades feel like.

tombate911

Paid Member

Snetterton - August 2021

Snetterton is a fair old 220 miles from me which normally takes around 4 hours driving with the trailer. But I don't mind the traveling down to Snetterton as the circuit is worth it at least once a year. The last two years we've done Snetterton and Cadwell Park one back to back weeks in the summer and it's been great. this year was no exception.

We set off on the Wednesday morning at 9am getting to Thetford for around 2am after some stops at the services, fueled up the cars at Tesco and did a shop for the few days we were away, all set to chill out the night before the track day with us staying in a house only 20 minutes from the circuit.

Thursday morning was my favourite type of conditions for a track day, warm 17-20 degrees, overcast skies and dry. We were at the circuit pretty early which is standard practice for us but there was already a few forum members unloading. I found our garage and popped the car off the trailer.

Few BMW's hanging around waiting for noise testing, funnily enough it turns out there was no noise testing and it was only drive by. It wasn't too bad as I did end up pulling a 99db static at Cadwell Park rising to 106db with a couple of pops on overrun. We spent a bit of time catching up and chatting with friends i haven't seen for months

Usual for me I am always apprehensive to get sighting laps out of the way, to check the car over and see how it feels and it runs correctly, one downside of the car not being on the road is that I don't get to test it like I did with the clio when I've had it in pieces.

First session was red flagged before I managed to get out on circuit but I found myself being the 3rd car in the pit lane ready to go out as the track reoppened.

I had set the tyres to the cold pressure. Stiffened up the rear dampers a few clips from what I had them set at Cadwell and cracked on knowing I could just stay out for the first session and let the car come up to working temperature.

Initial impressions during the first session was how much more mechanical grip the car has from the last time I was at Snetterton the previous year. Massively noticeable through the first corner and around Coram. I did notice the rear of the car a little bouncy in the first couple of sessions so softened off the rear dampers a couple of clicks and let the front full hard.

The rest of the day went off without any issues again for the E46. I checked it over a couple of times during the day but it ran flawlessly once again. Whether the inside of the engine and oil pump is as happy as the rest of the car is unknown, but I'll have a look at that over the next few months.

Spent the day with a lot of passengers onboard which is always good, the additional weight brings the lap times down slightly but I find it's always much better to share the laps with someone, always good fun taking someone new out too who's never been in the car before or not been in it for a while and they can see the progression of the car too,

Here's a video from a session with Ross Woods as passenger.

Just before lunch I managed to get out on track with Jonny and F0xy in their E36's which turned out to be one of my favorite sessions of the day.

This photo pretty much sums up the Track Obsession day. E46 chasing down various guises of Clio and Meganes. It was good to catch up with some familiar faces and chat to a few new faces too.

So I never look at lap times during the day and I can't seem them without pulling the data off the logger and looking at it on my laptop, but I do always look at it after the day, not always easy to find a clear lap at Snetterton without a passenger on Thursday but I managed a few and was really happy to find a couple of 2:15 laps mixed in there, this is 5 seconds faster than last time I was at Snetterton last august with the same engine, since then I've only been working on handling and mechanical grip so it's good to see the difference in lap times! I had quietly said to myself that I wanted to get down to 2:15 but I wasn't sure if I would be able to.

I've got loads of photos from the track day but I'll leave it there for now. I did my final session around 4:15 and on the final session the circuit was pretty much empty with only a couple of cars on track. This was a nice change from some of the busier track time in the morning. The car felt great and was reliable all day, I've been very lucky with it this year and I hope that it continues.

Few things I have taken away from Snetterton is I think the car would benifit from some stiffer springs now I've moved to AR1's. Snetterton managed to show this with the tight corners causing the car to dip the front end down and roll a little more than it used to, this is something I'll add to the list of changes before it goes out again, I've already got stiffer rear springs I just need to order some fronts to match.

Finish the post off with a pitlane video, I'm obviously biased but I love the straight 6 sound!

Snetterton is a fair old 220 miles from me which normally takes around 4 hours driving with the trailer. But I don't mind the traveling down to Snetterton as the circuit is worth it at least once a year. The last two years we've done Snetterton and Cadwell Park one back to back weeks in the summer and it's been great. this year was no exception.

We set off on the Wednesday morning at 9am getting to Thetford for around 2am after some stops at the services, fueled up the cars at Tesco and did a shop for the few days we were away, all set to chill out the night before the track day with us staying in a house only 20 minutes from the circuit.

Thursday morning was my favourite type of conditions for a track day, warm 17-20 degrees, overcast skies and dry. We were at the circuit pretty early which is standard practice for us but there was already a few forum members unloading. I found our garage and popped the car off the trailer.

Few BMW's hanging around waiting for noise testing, funnily enough it turns out there was no noise testing and it was only drive by. It wasn't too bad as I did end up pulling a 99db static at Cadwell Park rising to 106db with a couple of pops on overrun. We spent a bit of time catching up and chatting with friends i haven't seen for months

Usual for me I am always apprehensive to get sighting laps out of the way, to check the car over and see how it feels and it runs correctly, one downside of the car not being on the road is that I don't get to test it like I did with the clio when I've had it in pieces.

First session was red flagged before I managed to get out on circuit but I found myself being the 3rd car in the pit lane ready to go out as the track reoppened.

I had set the tyres to the cold pressure. Stiffened up the rear dampers a few clips from what I had them set at Cadwell and cracked on knowing I could just stay out for the first session and let the car come up to working temperature.

Initial impressions during the first session was how much more mechanical grip the car has from the last time I was at Snetterton the previous year. Massively noticeable through the first corner and around Coram. I did notice the rear of the car a little bouncy in the first couple of sessions so softened off the rear dampers a couple of clicks and let the front full hard.

The rest of the day went off without any issues again for the E46. I checked it over a couple of times during the day but it ran flawlessly once again. Whether the inside of the engine and oil pump is as happy as the rest of the car is unknown, but I'll have a look at that over the next few months.

Spent the day with a lot of passengers onboard which is always good, the additional weight brings the lap times down slightly but I find it's always much better to share the laps with someone, always good fun taking someone new out too who's never been in the car before or not been in it for a while and they can see the progression of the car too,

Here's a video from a session with Ross Woods as passenger.

Just before lunch I managed to get out on track with Jonny and F0xy in their E36's which turned out to be one of my favorite sessions of the day.

This photo pretty much sums up the Track Obsession day. E46 chasing down various guises of Clio and Meganes. It was good to catch up with some familiar faces and chat to a few new faces too.

So I never look at lap times during the day and I can't seem them without pulling the data off the logger and looking at it on my laptop, but I do always look at it after the day, not always easy to find a clear lap at Snetterton without a passenger on Thursday but I managed a few and was really happy to find a couple of 2:15 laps mixed in there, this is 5 seconds faster than last time I was at Snetterton last august with the same engine, since then I've only been working on handling and mechanical grip so it's good to see the difference in lap times! I had quietly said to myself that I wanted to get down to 2:15 but I wasn't sure if I would be able to.

I've got loads of photos from the track day but I'll leave it there for now. I did my final session around 4:15 and on the final session the circuit was pretty much empty with only a couple of cars on track. This was a nice change from some of the busier track time in the morning. The car felt great and was reliable all day, I've been very lucky with it this year and I hope that it continues.

Few things I have taken away from Snetterton is I think the car would benifit from some stiffer springs now I've moved to AR1's. Snetterton managed to show this with the tight corners causing the car to dip the front end down and roll a little more than it used to, this is something I'll add to the list of changes before it goes out again, I've already got stiffer rear springs I just need to order some fronts to match.

Finish the post off with a pitlane video, I'm obviously biased but I love the straight 6 sound!

Helpimonfire

Paid Member

The big 6 sounds amazing Tom

I meant to mention to you after following you through a slower corner that as you get your toe down, the front inside wheel is barely on the deck! Not that it seemed to slow you down at all!

I meant to mention to you after following you through a slower corner that as you get your toe down, the front inside wheel is barely on the deck! Not that it seemed to slow you down at all!

tombate911

Paid Member

Sat down this evening with a little bit of time and thought a small update wouldn't go amiss, I've been busy with a house i've bought recently which is a complete renovation back to a bare shell so time is a little thin on the ground at the moment.

It would have been lovely to have been able to park the car up after Snetterton and not have to touch it until the winter Oulton Park date but one thing has led to another, I was going to hold back on posting about this but might as well get the ball rolling...

Parked up on the drive after Snetterton and left it for a couple of weeks, I probably could have left it for a while after rebuilding the oil pump between Cadwell and Snetterton but I wanted to do a few jobs on the engine so rather than leaving it I thought preventative and development was better than trying to piece it back together if something goes again, I was very lucky at Cadwell.

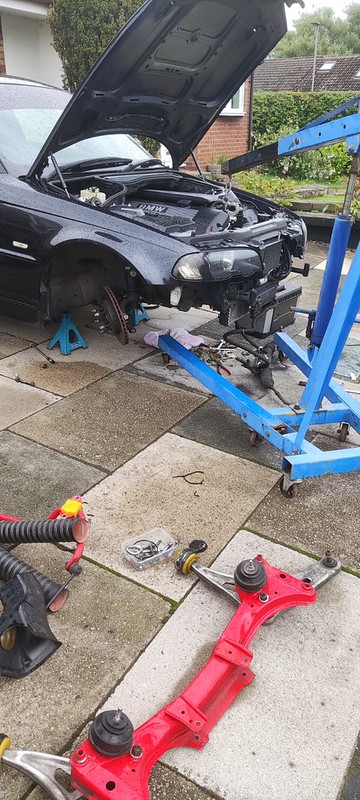

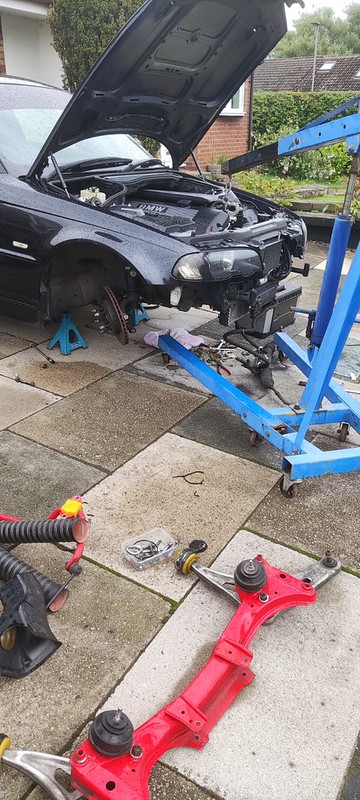

One hour later the front of the car removed

I pulled the engine out and got it mounted on the engine stand, at this point I wanted to do a few jobs before taking the car out again.

-Physically measure the cam lift, duration and centreline to see what the cams are, to find out if they actually match the spec I thought I bought,

-Check over the oil pump after the Cadwell issue, after going back to the standard pump I wanted to see if it was still tight or if any wear had shown from one day on track, considering twice it has been completely knackered after 5 days.

-Replace the oil pump chain, assuming the current chain could be worn / stretched (more on this later)

-I bought a chain tensioner from BMW from the S54 which I am going to fit to the M54.

To do these jobs It would have been a pain in the backside in the car so decided to pull the engine and get it on a stand in the garage so I can work on it properly.

First thing was to pull the sump off and check the oil pump, it was still torqued to what I set it at and there was zero wear between the shaft and the gear unlike I was getting on the VAC Kit, happy this set up is working for the moment.

There is considerable amount of slack in the chain though between the crank and the oil pump. This is something we noticed when the sump was off last month, I ordered a brand new Febi chain. Funnily the chain is exactly the same length as the old one, and you can see how much the chain can be pulled together in the photo here. At least the tensioner I am fitting will take up this slack.

Interesting we compared the M54B30 to a M50/M52 engine and the chain was much tighter on the M50 block as the oil pump seems to sit further away from the crank giving much less slack in the chain... Interesting as I think the slack in the chain was causing the oil pump gear to be snatched putting more force onto the gear/shaft interface.

The next job was to start measuring cam timing

Much easier to do this with it on the stand with the sump off and the rocker cover removed.

We set the engine at TDC with a DTI on the top of the piston to find actual TDC to remove any discrepancies with the single mass flywheel timing pin location.

Glued a timing wheel to the front of the crank pulley and used a piece of welding wire to mark where TDC was on the timing wheel.

We went through the process of putting a digital DTI on the top of the lifter and took a measurement every 3 degrees and input into excel to give the cam profile/lift vs crank angle for both the intake and exhaust.

Schrick list the cams as:

Intake - 272 - 10.9

Exhaust - 256 - 10.4

What we found was the cam duration and lift are pretty much exactly what they say they are. However the issue we did find was that the centrelines of the cams did not marry up with the specification sheets.

Schrick state they should be intake 126 and exhaust 114 degrees in their standard state when timed up.

Intake centreline was 136 degrees and exhaust centreline 111 degrees

Both cams being retarded but by different amounts,

Interestingly when you reach 6 degrees past TDC the timing blocks fall on the end of the cams perfectly.

As you would expect if you put the engine physically to TDC with a DTI a 3d printed 6 degree retarded timing block drops on the end of the cam.

So at the moment the cam timing was 6 degrees off, possibly from the timing pin hole in the flywheel, possibly from some other variables through the vanos system, I did the cam timing myself with the correct tooling and proceedure and when I check the timing when building the engine both blocks dropped on with the pin in the timing hole. There is also still a discrepency between the intlet timing block being a further 4-5 degrees retarded, either way when I time it back up I'll be doing it physically with a DTI and setting the cam centrelines to 114/126 then adjust the cam timing with the vanos. Whether it will make any difference to power when rebuilt, who knows as when on the dyno I did advance the intake cam at the top end and didn't really find much difference at peak rpm, mid range to makes a massive difference to power.

It would have been lovely to have been able to park the car up after Snetterton and not have to touch it until the winter Oulton Park date but one thing has led to another, I was going to hold back on posting about this but might as well get the ball rolling...

Parked up on the drive after Snetterton and left it for a couple of weeks, I probably could have left it for a while after rebuilding the oil pump between Cadwell and Snetterton but I wanted to do a few jobs on the engine so rather than leaving it I thought preventative and development was better than trying to piece it back together if something goes again, I was very lucky at Cadwell.

One hour later the front of the car removed

I pulled the engine out and got it mounted on the engine stand, at this point I wanted to do a few jobs before taking the car out again.

-Physically measure the cam lift, duration and centreline to see what the cams are, to find out if they actually match the spec I thought I bought,

-Check over the oil pump after the Cadwell issue, after going back to the standard pump I wanted to see if it was still tight or if any wear had shown from one day on track, considering twice it has been completely knackered after 5 days.

-Replace the oil pump chain, assuming the current chain could be worn / stretched (more on this later)

-I bought a chain tensioner from BMW from the S54 which I am going to fit to the M54.

To do these jobs It would have been a pain in the backside in the car so decided to pull the engine and get it on a stand in the garage so I can work on it properly.

First thing was to pull the sump off and check the oil pump, it was still torqued to what I set it at and there was zero wear between the shaft and the gear unlike I was getting on the VAC Kit, happy this set up is working for the moment.

There is considerable amount of slack in the chain though between the crank and the oil pump. This is something we noticed when the sump was off last month, I ordered a brand new Febi chain. Funnily the chain is exactly the same length as the old one, and you can see how much the chain can be pulled together in the photo here. At least the tensioner I am fitting will take up this slack.

Interesting we compared the M54B30 to a M50/M52 engine and the chain was much tighter on the M50 block as the oil pump seems to sit further away from the crank giving much less slack in the chain... Interesting as I think the slack in the chain was causing the oil pump gear to be snatched putting more force onto the gear/shaft interface.

The next job was to start measuring cam timing

Much easier to do this with it on the stand with the sump off and the rocker cover removed.

We set the engine at TDC with a DTI on the top of the piston to find actual TDC to remove any discrepancies with the single mass flywheel timing pin location.

Glued a timing wheel to the front of the crank pulley and used a piece of welding wire to mark where TDC was on the timing wheel.

We went through the process of putting a digital DTI on the top of the lifter and took a measurement every 3 degrees and input into excel to give the cam profile/lift vs crank angle for both the intake and exhaust.

Schrick list the cams as:

Intake - 272 - 10.9

Exhaust - 256 - 10.4

What we found was the cam duration and lift are pretty much exactly what they say they are. However the issue we did find was that the centrelines of the cams did not marry up with the specification sheets.

Schrick state they should be intake 126 and exhaust 114 degrees in their standard state when timed up.

Intake centreline was 136 degrees and exhaust centreline 111 degrees

Both cams being retarded but by different amounts,

Interestingly when you reach 6 degrees past TDC the timing blocks fall on the end of the cams perfectly.

As you would expect if you put the engine physically to TDC with a DTI a 3d printed 6 degree retarded timing block drops on the end of the cam.

So at the moment the cam timing was 6 degrees off, possibly from the timing pin hole in the flywheel, possibly from some other variables through the vanos system, I did the cam timing myself with the correct tooling and proceedure and when I check the timing when building the engine both blocks dropped on with the pin in the timing hole. There is also still a discrepency between the intlet timing block being a further 4-5 degrees retarded, either way when I time it back up I'll be doing it physically with a DTI and setting the cam centrelines to 114/126 then adjust the cam timing with the vanos. Whether it will make any difference to power when rebuilt, who knows as when on the dyno I did advance the intake cam at the top end and didn't really find much difference at peak rpm, mid range to makes a massive difference to power.

tombate911

Paid Member

Part 2

While I was taking the front timing cover off for the fitting of the new chain tensioner you have to remove 3 small head bolts from the front of the block which is part of the head gasket, I decided while I'm this far in I will pop the head off and have a look at the insides of the engine and the bores, I did have a niggling thought in the back of my mind as a friends engine was stripped the week prior and was showing major bore wear after only a couple of track days after being machined... Without going into massive detail there is a thread about all this now in the Piston Heads Engine section.

Head off and the front timing case

Looking down into the bores, my worries were confirmed and all 6 bores have shown signs of wear/polishing. It doesn't show up as well on photos and it more visible on the exhaust side of the engine. I will get some bet photos now the pistons are out of the bores and add them to the thread.

Initially the thought was worn bores but we later confirmed this wasn't the case with the pistons measuring exact BMW specification of 83.95mm, we measured each of the bores in 4 different directions at the top, middle and bottom of the bores and the bore clearance was between a min of 0.057 and 0.070 which is half of the BMW max of 0.15mm cylinder to bore clearance. There has been a lot of discussion around this so I've held back posting about it for now but it turns out 3 engines all honed by the same machine shop are showing the same wear, all with less than 7 days use of them. I'm taking the thought process that is it something to do with hone, depth, quality or similar which is causing issues with oil retention on the walls causing the wear? Possibly? I don't know much about it to be able to be certain. I do know though that I won't be just putting the head back on without doing something about it. At least the bores measure up fine and there is still some material to hone it again and rebuild.

I've since stripped the bottom end down completely, checked over the pistons, rods and bearings, everything looks really good, I was expecting more wear to the rod bearings and main bearings considering I've been reving this engine hard to 7,000rpm with the known harmonic issues, I also thought the lower oil pressure of 30psi at Cadwell Park might have had an impact on the bearings but all seems ok as it's been stripped down.

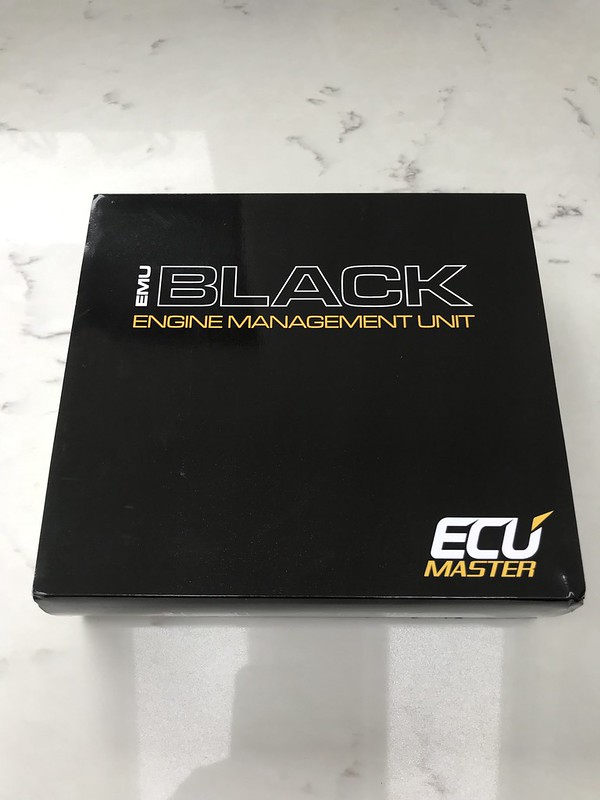

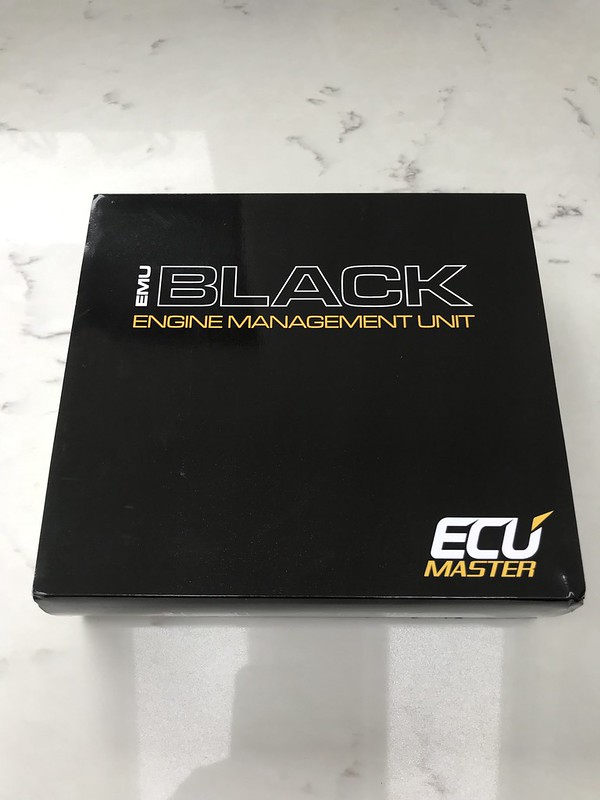

The next bit of exciting news, I did post this on social media so some people will know about this exciting change, I've spent a lot of time changing and mapping the MS43 standard ECU to work with my set up with the new engine and M50 inlet. I decided to finally order a standalone ECU. Decided to go with the ECU Master black for the following reasons.

On board CANBUS which supports the standard BMW Clocks and will integrate with my CANBUS logger so no need to add a new dashboard to the car.

Dual H bridges so It will work with drive by wire, From what I've seen so far the set up for the throttle mapping to support the Electronic throttle body and electronic throttle pedal is really good.

Ability to work with the Dual Vanos which is full variable on the M54

I have a number of friends now that are using the black and classic with good success, it's good to use products friends are using to share knowledge and experience.

So with moving towards standalone management I didn't want to just buy some of the plug and play adaptors, I've decided to chop off the standard ECU plugs and pin out the wires into the ECU Master plugs, I can make my own changes to the wiring and add in an additional wiring as I work through it, I have been spending time in the evenings working through the pin out, inputting it into excel, testing the wiring of the factory loom assigning the wires to the ECU Master pin out.

Standard engine wiring loom about to go under the knife, I will be removing all the wires that are no longer needed from the loom such as MAF wiring, the emissions wiring and idle control valve which I wasn't using anyway.

The next steps are to organise the rehoning of the engine block so I can work on building the engine back up and continue to work through the wiring and building of a base map to run the car, I've decided to build the base map for the ECU from scratch so I know everything is correctly configured and set up correctly rather than starting with a random file from the internet.

The plan is to run the engine in on the standard ECU and then swap the wiring and ECU over and map it once the engine is ran in and working correctly.

While I was taking the front timing cover off for the fitting of the new chain tensioner you have to remove 3 small head bolts from the front of the block which is part of the head gasket, I decided while I'm this far in I will pop the head off and have a look at the insides of the engine and the bores, I did have a niggling thought in the back of my mind as a friends engine was stripped the week prior and was showing major bore wear after only a couple of track days after being machined... Without going into massive detail there is a thread about all this now in the Piston Heads Engine section.

Head off and the front timing case

Looking down into the bores, my worries were confirmed and all 6 bores have shown signs of wear/polishing. It doesn't show up as well on photos and it more visible on the exhaust side of the engine. I will get some bet photos now the pistons are out of the bores and add them to the thread.

Initially the thought was worn bores but we later confirmed this wasn't the case with the pistons measuring exact BMW specification of 83.95mm, we measured each of the bores in 4 different directions at the top, middle and bottom of the bores and the bore clearance was between a min of 0.057 and 0.070 which is half of the BMW max of 0.15mm cylinder to bore clearance. There has been a lot of discussion around this so I've held back posting about it for now but it turns out 3 engines all honed by the same machine shop are showing the same wear, all with less than 7 days use of them. I'm taking the thought process that is it something to do with hone, depth, quality or similar which is causing issues with oil retention on the walls causing the wear? Possibly? I don't know much about it to be able to be certain. I do know though that I won't be just putting the head back on without doing something about it. At least the bores measure up fine and there is still some material to hone it again and rebuild.

I've since stripped the bottom end down completely, checked over the pistons, rods and bearings, everything looks really good, I was expecting more wear to the rod bearings and main bearings considering I've been reving this engine hard to 7,000rpm with the known harmonic issues, I also thought the lower oil pressure of 30psi at Cadwell Park might have had an impact on the bearings but all seems ok as it's been stripped down.

The next bit of exciting news, I did post this on social media so some people will know about this exciting change, I've spent a lot of time changing and mapping the MS43 standard ECU to work with my set up with the new engine and M50 inlet. I decided to finally order a standalone ECU. Decided to go with the ECU Master black for the following reasons.

On board CANBUS which supports the standard BMW Clocks and will integrate with my CANBUS logger so no need to add a new dashboard to the car.

Dual H bridges so It will work with drive by wire, From what I've seen so far the set up for the throttle mapping to support the Electronic throttle body and electronic throttle pedal is really good.

Ability to work with the Dual Vanos which is full variable on the M54

I have a number of friends now that are using the black and classic with good success, it's good to use products friends are using to share knowledge and experience.

So with moving towards standalone management I didn't want to just buy some of the plug and play adaptors, I've decided to chop off the standard ECU plugs and pin out the wires into the ECU Master plugs, I can make my own changes to the wiring and add in an additional wiring as I work through it, I have been spending time in the evenings working through the pin out, inputting it into excel, testing the wiring of the factory loom assigning the wires to the ECU Master pin out.

Standard engine wiring loom about to go under the knife, I will be removing all the wires that are no longer needed from the loom such as MAF wiring, the emissions wiring and idle control valve which I wasn't using anyway.

The next steps are to organise the rehoning of the engine block so I can work on building the engine back up and continue to work through the wiring and building of a base map to run the car, I've decided to build the base map for the ECU from scratch so I know everything is correctly configured and set up correctly rather than starting with a random file from the internet.

The plan is to run the engine in on the standard ECU and then swap the wiring and ECU over and map it once the engine is ran in and working correctly.

Helpimonfire

Paid Member

Seems odd that 3 engines from the same machine shop are having the same issues, have you been in contact with them to see if they'll do anything about it?

Other than that though, I always admire the work you put in to this car, and seeing it first hand go flying past me was equally impressive. I love how you aren't phased at all by the work you're undertaking here!

Other than that though, I always admire the work you put in to this car, and seeing it first hand go flying past me was equally impressive. I love how you aren't phased at all by the work you're undertaking here!

Frightened that I’m gonna catch you?!

Great write up mate. Didn’t understand most of it as usual but nice of you to include pictures for me

Great write up mate. Didn’t understand most of it as usual but nice of you to include pictures for me